Coolant Distribution Units (CDU) for Data Center Cooling

Data center liquid cooling is an efficient and environmentally friendly cooling method for managing the heat generated by the numerous devices in a data center. Compared with traditional air cooling methods, liquid cooling technology has higher heat transfer efficiency, thereby improving equipment performance, reducing energy consumption and operating costs. Liquid cooling is a new technology that uses liquid as a refrigerant to dissipate heat from heat-generating components. Building a liquid-cooled data center based on liquid-cooling technology and liquid-cooled servers and other equipment can reduce heat dissipation energy consumption by nearly 90%, and the overall data center energy consumption can be reduced by nearly 36%, which is an important condition for improving data center performance.

Cooling Technology And Solutions

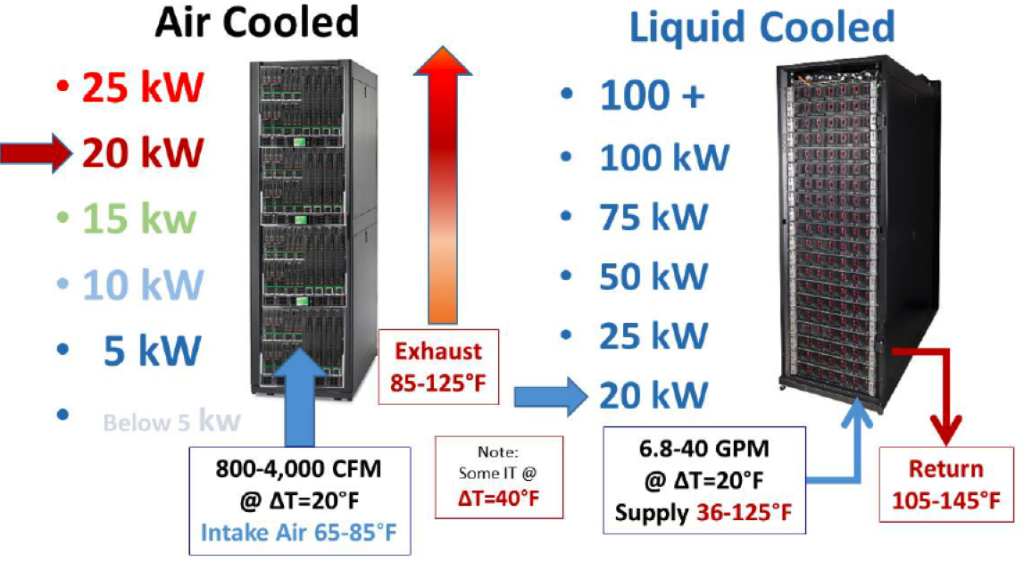

The current data center cooling technology is mainly based on air cooling. Air cooling is to use air as a refrigerant to transfer the heat emitted by the server motherboard, CPU, etc. to the radiator module, and then use fans or air conditioners to blow the heat away. This is the main reason why cooling systems consume nearly half of a data center’s electricity.

Air cooling includes direct air natural cooling technology and indirect air natural cooling technology. Direct air cooling can be based on the outdoor temperature, combined with mechanical refrigeration to dissipate heat for the internal equipment of the data center. This technology has high energy efficiency, but the uncertainty of air quality will bring greater risks, especially if the outdoor air humidity is too high or too much harmful gases, which can cause damage to IT equipment. In order to avoid this situation, data centers in recent years have begun to adopt indirect air natural cooling technology, which cools the indoor hot air through the outdoor cold air through the air heat exchanger, and prevents the outdoor air from entering the data center, which is less affected by the environment.

These two air-cooling technologies have relatively high efficiency, but they have high requirements on the environment and installation, which will cause loss to IT equipment and reduce reliability. As the scale of data centers increases and the power density of a single cabinet increases, higher requirements are placed on cooling. Therefore, liquid cooling technology for next-generation IT systems emerges as the times require.

As a new heat dissipation method, liquid cooling realizes system heat exchange through external cooling water or chilled water system. Specifically, liquid with high specific heat capacity is used as the heat transfer working medium to meet the cooling requirements of IT equipment (such as servers).

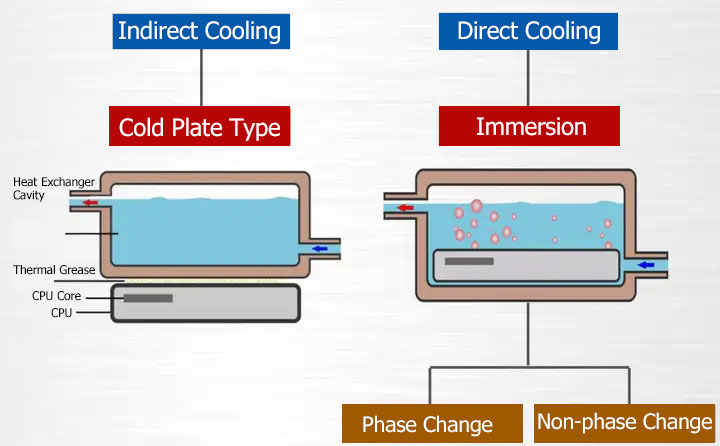

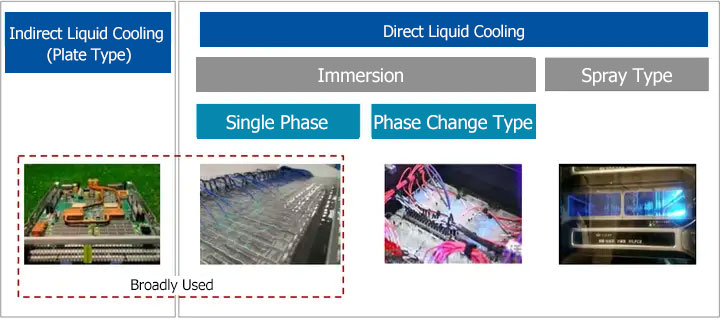

At present, the mainstream solutions based on liquid cooling technology include cold plate liquid cooling and immersion liquid cooling.

Cold plate liquid cooling is also called indirect liquid cooling, that is, the refrigerant is separated from the cooled object without direct contact. The heat of the object to be cooled is transferred to the refrigerant through high-efficiency heat conduction components such as liquid cooling. Generally, cold plate liquid cooling is only used to cool key components such as CPU and memory, which only accounts for about half of the total heat generation. Therefore, it needs to be combined with air cooling to reduce the number of fans and power consumption of IT equipment, and achieve a large degree of energy saving.

Immersion liquid cooling is also called direct liquid cooling. It is to immerse all high-heat components such as server motherboards, CPUs, and memory into cooling liquid, and use cooling liquid instead of air to cool IT equipment, so that the cooled objects and The refrigerant is in direct contact, so that the cooling uniformity of the heating components is better, and a liquid with a phase change at a certain temperature can be selected.

Compared with air cooling, liquid cooling has more obvious advantages in heat exchange medium, driving components, heat dissipation capacity, energy saving, noise reduction, construction cost and site selection.

Advantages Of Coolant Distribution Units (CDU)

- Energy saving

90%-95% reduction in heat dissipation energy consumption; 10%-20% reduction in IT equipment energy consumption.

- Cut costs

The construction cost is lower than that of the traditional computer room.

- Easy to install

Less restrictions, PUE meets environmental and low-carbon requirements.

- Safe and reliable

Coolant can improve the operating environment of IT equipment, making it safer and more reliable.

- Low carbon and environmental protection

Solve power resources, save energy and reduce consumption, and the PUE can be close to 1.0.

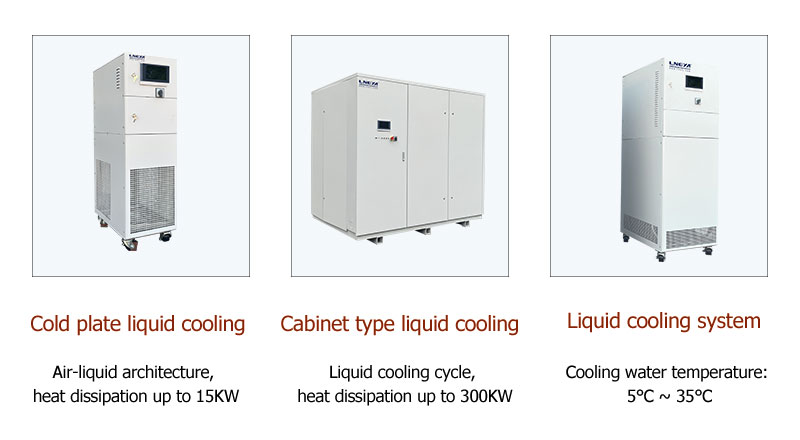

Products And Solutions

Model One: 15 ~ 150kW

| Model | ZLFQ-15 | ZLFQ-25 | ZLFQ-50 | ZLFQ-75 | ZLFQ-100 | ZLFQ-150 |

| Temp range | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ |

| Cooling water | 5℃~30℃ Adopt Siemens/Honeywell regulating valve to control cooling water flow | |||||

| Temperature control accuracy | ±0.2℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ |

| flow control | 10~25L/min | 25~50L/min | 40~110L/min | 70~150L/min | 150~250L/min | 200~400L/min |

| The flow control is adjusted by frequency converter, the accuracy is ±0.3L/min | ||||||

| Cooling capacity (MAX) | 15kW | 25kW | 50kW | 75kW | 100kW | 150kW |

| Storage volume | 15L | 30L | 60L | 100L | 150L | 200L |

| Brine | Water, silicone oil, fluorinated liquid, ethylene glycol aqueous solution, etc. | |||||

| controller | PLC, fuzzy PID control algorithm, with cascade control algorithm | |||||

| temperature control | Heat transfer medium outlet temperature control mode, with cascade control algorithm | |||||

| letter of agreement | Ethernet interface TCP/IP protocol | |||||

| RS485 interface modbus RTU protocol | ||||||

| Device Internal Temperature Feedback | Equipment heat transfer medium outlet temperature, medium inlet temperature, cooling water temperature | |||||

| tank level | Import and export pressure sensor detection, cooling water pressure detection | |||||

| Medium pipeline | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 |

| Heat Exchanger | Plate heat exchanger, special attention: need to use clean factory water | |||||

| operation panel | Wuxi Guanya customized 7-inch color touch screen, temperature curve displayEXCEL data export | |||||

| Security | With self-diagnosis function; phase sequence and phase failure protector; pressure protection, overload relay, thermal protection device and other safety protection functions. | |||||

| In and out interface size | G3/4 | G1 | G1 | DN32 | DN40 | DN50 |

| Cooling water interface | G3/4 | G1 | DN40 | DN50 | DN50 | DN65 |

| cooling method | Water-cooled, the factory water temperature is lower than the minimum temperature provided by the equipment by more than 3°C, and the water temperature fluctuation is ≤3°C | |||||

| Cooling water flow 7~20℃ | 2.5m³/h | 4m³/h | 8m³/h | 13m³/h | 17m³/h | 25m³/h |

| power supply | ||||||

| 380V 50HZ | 1kW | 1.5kW | 3kW | 4kW | 5kW | 6kW |

| shell | Cold-rolled sheet spray RAL7035 | |||||

Model Two: 200 ~ 500kW

| Model | ZLFQ-200 | ZLFQ-250 | ZLFQ-300 | ZLFQ-400 | ZLFQ-500 |

| Temp range | +5℃~35℃ | ||||

| Temp accuracy | ±0.5℃ | ||||

| Flow control | 15~30m³/h | 20~35m³/h | 25~40m³/h | 30~60m³/h | 40~70m³/h |

| Flow control is adjusted by frequency converter | |||||

| Cooling capacity(MAX) | 200kW | 250kW | 300kW | 400kW | 500kW |

| Storage volume | 250L | 300L | 600L | 1000L | 1200L |

| Cooling System | The plant service water exchanges heat with the brine, and the brine provides cooling capacity for the heating equipment | ||||

| Medium | Water, silicone oil, fluorinated liquid, ethylene glycol aqueous solution, etc. | ||||

| controller | PLC, fuzzy PID control algorithm, with cascade control algorithm | ||||

| temperature control | Heat transfer medium outlet temperature control mode式 | ||||

| letter of agreement | Ethernet interface TCP/IP protocol | ||||

| RS485 interface modbus RTU protocol | |||||

| Device Internal Temperature Feedback | Equipment heat transfer medium outlet temperature, medium inlet temperature, cooling water temperature | ||||

| tank level | Pressure sensor real-time monitoring | ||||

| Medium pipeline | SUS304 | ||||

| System pressure | Using the pressure sensor to detect and display on the touch screen | ||||

| Heat Exchanger | Plate heat exchanger, special attention: need to use clean factory water | ||||

| operation panel | Wuxi Guanya customized 7-inch color touch screen, temperature curve displayEXCEL data export | ||||

| Security | With self-diagnosis function; phase sequence and phase failure protector; pressure protection, overload relay, thermal protection device and other safety protection functions. | ||||

| In and out interface size | DN65 | DN65 | DN65 | DN80 | DN80 |

| Cooling water interface | DN80 | DN80 | DN100 | DN100 | DN125 |

| cooling method | Water-cooled, the factory water temperature is lower than the minimum temperature provided by the equipment by more than 3°C, and the water temperature fluctuation is ≤3°C | ||||

| Cooling water flow 7~20℃ | 34m³/h | 43m³/h | 51m³/h | 69m³/h | 86m³/h |

| Power supply 380V 50HZ | 7kW | 7kW | 8kW | 9kW | 13kW |

| shell | Cold-rolled sheet spray RAL7035 | ||||

We provide complete temperature control system design and manufacturing. From standard models to complete customized products up to 1000 tons. We specialize in customer service and are dedicated to helping each customer have the optimal temperature control system for their specific need.

We provide non-standard customized solutions.

Email: lilia@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

Why Choose Us?

LNEYA is a professional temperature control equipment manufacturer with decades of experience in research and development in the field of high and low temperature control, and its products are used in various industries. We can design any temperature control system according to your requirements, whether it is accessories: pumps, heat exchangers, condensers, etc., or refrigeration types: air-cooled, water-cooled, multiple cooling circuits, etc.

Our Services

Customized Designs—Our products can be built in any type of variation to your exact specifications.

Competitive Pricing—We offer great prices on equipment that exceeds industry standards, guaranteeing the highest quality.

Same Day Quotes—Get a quote for your project today! We often provide custom quotes in as little as 30 minutes.

24/7 Customer Service—We are always here for you. Whether you have a question or need a quote, there’s always somebody here to communicate with you 24/7.

Durable and Reliable Equipment—Our products are built with premium-grade materials, and we offer competitive warranties on all custom chillers.

Contact Us Today

Contact us today and learn more about our abilities in manufacturing custom chillers. Our staff welcomes any application challenges concerning your custom chillers.

Dear Sir/Madam, please fill out the form below and one of our team members will be in touch shortly!

Email: lilia@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

LNEYA

LNEYA

简体中文

简体中文