Types and Advantages of Chillers

Contact us today for the perfect temperature control solution

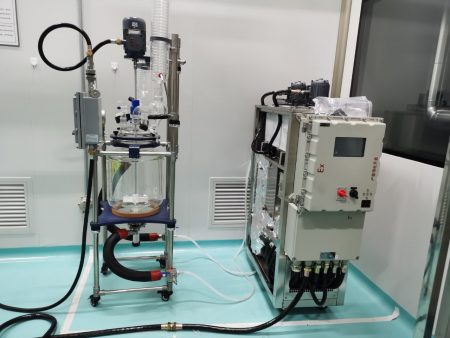

A chiller is a device used for refrigeration. It can cool water and transport it to the refrigeration equipment through pipelines to reduce the temperature of the equipment and maintain its normal operation. According to different industrial applications and occasions, chillers can be divided into many types, each type has its unique advantages and scope of application.

1. Air-cooled chiller

Air-cooled chiller is a cooling device that uses air flow as the cooling medium. Compared with water-cooled chillers, its biggest advantage is that it does not require cooling water, thus eliminating the cost and maintenance of water pumps and water coolers. In addition, because its units are independent, installation and maintenance are relatively simple.

2. Water-cooled chiller

Water-cooled chiller is a cooling equipment that uses water as the cooling medium. Compared with air-cooled chillers, it requires additional water pumps and water coolers, but it can take advantage of the high thermal conductivity of water to provide higher system cooling under the same cooling conditions.

3. Rolling piston chiller

A rolling piston chiller is a cooling device that uses a rolling piston to compress refrigerant. Compared with traditional screw compression cooling equipment, its main advantages lie in high energy efficiency and operational stability. In addition, it can operate under high thermal efficiency loads, making it suitable for most industrial and commercial applications.

4. Screw compression chiller

A screw compression chiller is a device that uses a screw inside to compress the refrigerant to achieve cooling. Compared with rolling piston chillers, its advantages are higher cooling capacity and lower vibration noise. In addition, it can be used in a wider range of industrial and commercial situations.

5. Magnetic levitation screw compression chiller

The magnetic levitation screw compression chiller introduces magnetic levitation technology, which eliminates the mechanical friction between the screws in traditional screw compression chillers. Compared with traditional screw compression chillers, it has higher energy efficiency and operational stability, while also reducing maintenance and operating costs.

6. Low temperature chiller

A low-temperature chiller is a piece of equipment specially designed for cooling to very low temperatures. Its main application areas include food industry, pharmaceutical industry, petrochemical industry, etc. Compared with traditional refrigeration equipment, low-temperature chillers have higher refrigeration capacity and lower temperatures, and are suitable for long-term refrigeration of items that require strict storage and production refrigeration formulas.

To sum up, different types of chillers have their own advantages and scope of application. When choosing a chiller that suits you, you should conduct a comprehensive analysis based on the actual situation to achieve the effect of meeting production and use needs.

We provide complete temperature control systems design and manufacturing. From standard models to complete customized products up to 900 tons. We specialize in customer service and are dedicated to helping each customer have the optimal temperature control system for their specific need.

We provide non-standard customized solutions. Both single cooling chillers and cooling & heating combo units are available.

Email: info@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

Recirculating Chillers / Refrigerated Circulator

The chiller can be widely used in various industries and laboratories, and supports customized design.

| Temperature range | -25°C ~ +30°C series | -45°C ~ +30°C series | -60°C ~ -20°C series | -80°C ~ -20°C series | -120°C ~ -70°C series | ||||

| Cooling Capacity | 0.8 ~ 30kW | 0.75 ~ 12kW | 0.4 ~ 6kW | 0.2 ~ 6kW | 0.3 ~ 5kW | ||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

Water Chillers / Small Chillers

Water Chillers / Small Chillers

The chiller can be widely used in various industries and laboratories, and supports customized design.

| Temperature range | -18°C ~ +30°C | +5°C ~ +35°C series | |||||||

| Cooling Capacity | 0.35 ~ 0.9kW | 1.8 ~ 50kW | |||||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

Low Temperature Chillers

We specialize in the production of low-temperature chillers with a temperature control range as low as -150°C, which can meet the refrigeration needs of different industries.

| Temperature range | -25°C ~ -5°C series | -45°C ~ -10°C series | -60°C ~ -10°C series | -80°C ~ -30°C series | -110°C ~ -50°C series | -150°C ~ -110°C series | |||

| Cooling Capacity | 12 ~ 360kW | 6 ~ 180kW | 6 ~ 180kW | 4 ~ 180kW | 2 ~ 120kW | 2.5 ~ 11kW | |||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

High Temperature Chillers

The chiller can be widely used in various industries and laboratories, and supports customized design.

| Temperature range | +5°C ~ +40°C | -25°C ~ +40°C | -45°C ~ +40°C | -80°C ~ +80°C | -100°C ~ +80°C | ||||

| Cooling Capacity | 6 ~ 40kW | 2 ~ 15kW | 1 ~ 8kW | 0.6 ~ 3kW | 1.5 ~ 3kW | ||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

Cooling and Heating Chillers

Temperature Control Range: -120°C to +350°C

cooling and heating thermostat, widely used in various industry.

| Temperature range | -10 ~ +150°C series | -25 ~ +200°C series | -25 ~ +300°C series | -45 ~ +250°C series | -45 ~ +300°C series | -60 ~ +250°C series | -60 ~ +300°C series | -70 ~ +250°C series | -80 ~ +250°C series | -90 ~ +250°C series | -100 ~ +100°C series | ||

| Cooling Capacity | 1.5 ~ 15kW | 1 ~ 200kW | 1 ~ 200kW | 0.45 ~ 200kW | 0.9 ~ 25kW | 0.25 ~ 60kW | 0.75 ~ 25kW | 0.4 ~ 15kW | 0.3 ~ 80kW | 0.2 ~ 80kW | 0.45 ~ 80kW | ||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||||||

Recirculating Heater Chillers

Temperature Control Range: -45°C to +250°C

| Temperature range | -25°C ~ +200°C series | -45°C ~ +250°C series | |||||||

| Cooling Capacity | 1 ~ 15kW | 0.25 ~ 15kW | |||||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

LNEYA

LNEYA

简体中文

简体中文