Battery Thermal Management System

Contact us today for the perfect temperature control solution

Overview of battery thermal management system

As the power source of electric vehicles, power batteries are a key part of improving vehicle performance and reducing costs. Its temperature characteristics directly affect the performance, life and durability of electric vehicles. Currently, the most widely used batteries include lead-acid batteries, nickel-metal hydride batteries and lithium batteries. Lithium-ion batteries are currently the preferred power battery for electric vehicles due to their large specific energy, long cycle life, low self-discharge rate, wide allowable operating temperature range, and good low-temperature effect.

The requirements for thermal management of lithium-ion battery packs are to reasonably design the battery pack structure based on the heating mechanism of lithium-ion batteries, select appropriate thermal management methods, and rationally design thermal management strategies to ensure that each single cell in the battery pack operates within a reasonable temperature range. At the same time, try to maintain temperature uniformity among each battery and battery module in the bag.

Battery thermal management system target

Thermal management objectives ensure the realization of design indicators for safe and stable operation of electric vehicles. It is a programmatic document for the design of thermal management systems and serves as a guide.

The setting of thermal management goals includes not only the special technical indicators of the thermal management system itself, but also comprehensive considerations of other aspects of the vehicle design (such as coordination with other component systems, system operation convenience, safety, cost control, etc.). Management system requirements.

The setting of thermal management goals needs to consider the following aspects:

Ensure that the battery pack is within the safe operating temperature range under different operating conditions

Reliability requirements (collision, external fire, water wading, extreme high and low temperatures, etc.)

Battery pack overall temperature uniformity index

Usage performance requirements (such as fast charging performance of the battery pack under high charging power, long battery life in high and low temperature environments)

Response time indicator of temperature control (rapid cooling or rapid heating)

Energy efficiency indicators of thermal management systems (fluid cooling loop flow and pressure drop parameters)

Intelligent control requirements

System cost considerations (economics)

Maintenance convenience

Battery thermal management systems

| Model | CNYL -45 |

| Cooling Capacity | 45KW |

| Temperature Control Accuracy | ±0.5℃ Real-time temperature record |

| Secondary Refrigerant | Ethylene glycol antifreeze, fully enclosed design of refrigerant circulation system |

| Refrigerant | R410A |

| Flow | 300L/min~400L/min Set display history |

| Low Pressure electrical | Schneider/Siemens |

| Display Screen | 7 inch color touch screen |

| Power | 380V 50HZ Choose 220V60HZ 460V 60HZ |

| Shell Material | Cold-rolled sheet spray REL7035 |

| Internal Piping | SUS304 |

| Model | CNYL-5 | CNYL-8.5 |

| Cooling Capacity | 5KW | 8.5KW |

| Accuracy | ±0.5℃ Real-time temperature record | ±0.5℃ Real-time temperature record |

| Minimum water inlet temperature | 15℃(Can be customized according to the battery system) | 13℃(Can be customized according to the battery system) |

| System pressure sensor detection | Liquid outlet pressure, liquid inlet pressure, refrigeration system high and low pressure | |

| COP | *2.0 | *2.2 |

| Compressor | Hermetic compressor (1 set) | 34cm3 /revFully enclosed scroll compressor (1 set) |

| Refrigerant | R410A | R410A |

| Display | 7 inch color touch screen | 7 inch color touch screen |

| Ambient operating temperature range | -45℃~55℃ | |

| Control voltage range | 18-32V | 18-32V |

| Refrigeration high pressure maximum power | 2.2KW | 3.5KW |

| Refrigeration average input electric power (kW) | +1.5kwadjustable frequency | +2kwadjustable frequency |

| COP | *2.0 | *2.2 |

| Model | CHDYL-4 |

| Cooling Capacity | 4KW |

| Accuracy | ±1℃ Real-time temperature record |

| Compressor | Hermetic compressor (1 set) |

| Refrigerant | R134A |

| Display | 7 inch color touch screen |

| Control system | PLC |

| Communication | CAN |

| Ambient operating temperature range | -45℃~55℃ |

We provide complete temperature control system design and manufacturing. From standard models to complete customized products up to 1000 tons. We specialize in customer service and are dedicated to helping each customer have the optimal temperature control system for their specific need.

We provide non-standard customized solutions.

Email: info@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

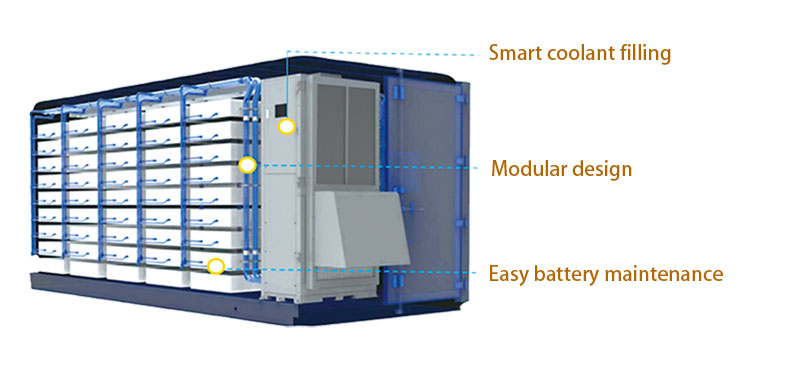

Battery thermal management system structure

The power battery pack is composed of a large number of single cells, and its structural form is related to many factors such as the structure and quantity of single cells, electrical connection methods, cooling methods, and vehicle structural layout. The structural design of the power battery pack covers many aspects such as electricity, heat/flow, and machinery, and requires integrated design. After determining the preliminary plan, multiple iterative calculations and coordination are required to meet the overall space allocation, thermal control needs, electrical characteristics and other requirements before the final design plan is determined.

Since the thermal control subsystem of the power battery pack is associated with the battery pack structure, the prerequisite for thermal/flow simulation analysis of the thermal management system is to obtain detailed structural information and the matching thermal control hardware design plan.

Hardware composition of battery thermal management system

Cooling system

The temperature environment in which the battery works must meet specific requirements. For example, the general ambient temperature of lithium iron phosphate batteries is -20°C to 60°C. The battery will continuously generate heat during the charging and discharging process. If this heat is not dissipated in time, the internal temperature of the battery can easily overheat or even cause thermal runaway. Therefore, a cooling system for the battery pack is essential.

According to the different cooling media, the cooling system can be divided into air cooling (air cooling), liquid air cooling and phase change liquid cooling. The heat dissipation capabilities of these three cooling methods are gradually enhanced, and the complexity of the cooling system is also gradually increased. At present, the cost of phase change cooling is relatively high. Currently, air cooling and liquid cooling are often used in engineering technology.

(1) Air cooling mode

The main purpose is to force cold air to flow through the battery surface for heat exchange and cooling. This solution is greatly affected by the external environment, especially in hot weather, and cold air needs to be introduced from the passenger compartment. The density of the gas is very small and the volume heat capacity is small. A large flow rate is required to achieve efficient heat exchange, and the overall heat exchange efficiency is relatively low. In addition, because the inlet air temperature is difficult to control, the battery temperature is also difficult to control. The advantages of this cooling method are that the system cost is very low and the technology is relatively mature. It is still used in some hybrid vehicles that use less battery modules.

(2) Liquid cooling mode

The refrigerant can be pure water, 50% ethylene glycol aqueous solution, pure ethylene glycol, air conditioning refrigerant working fluid, etc. The system structure of liquid cooling mode is shown in the figure below. Generally, a heat exchanger is added to couple with the refrigeration cycle to remove the heat from the battery through the refrigerant.

The entire system mainly includes: pump, heat exchanger, battery cooling plate, PTC heater, and expansion tank. When the battery needs to be cooled, the battery exchanges heat with the coolant through the heat sink. The heated coolant is sent into the heat exchanger by the electronic water pump. The refrigerant is passed into one side of the heat exchanger and the coolant is passed into the other side. The two fully exchange heat in the heat exchanger, the heat is taken away by the refrigerant, and the cold water flows out of the heat exchanger and into the battery, forming a cycle. When the battery needs to be heated, close the refrigeration circuit and turn on the PTC heater. The coolant is heated and sent into the battery to heat the battery through the heat sink. The temperature of the cooling heat can be controlled by controlling the on and off of the refrigeration circuit and the PTC heating power, thereby controlling the internal temperature of the battery. This solution system is more complex and the cost is higher.

(3) Air-cooling/water-cooling hybrid cooling system

There are two key components in the air-cooling/water-cooling hybrid cooling system: one is a water-cooled battery cooler, and the other is an air-cooled battery radiator. The air-cooled/water-cooled hybrid cooling system has the advantages of compact system, good performance, and economical and energy-saving in low-temperature environments. However, this system is complex, costly, complex to control, and requires high reliability.

Cooling systems can also be divided into active cooling and passive cooling based on the source of energy supply. Usually the passive cooling system directly discharges the hot air inside the battery from the car body, while the active cooling system usually has an internal circulation system and actively adjusts according to the temperature of the battery system to achieve the best thermal control effect. Passive cooling has the advantages of simple structure, few parts, and low cost, and is widely used in battery cooling system design.

According to the heat generation principle of lithium-ion batteries, heat transfer cooling methods, and performance comparisons between air-cooled and liquid-cooled heat dissipation solutions, generally speaking, liquid-cooled heat dissipation is better than air-cooled, and liquid-cooled heat dissipation will be a major solution suitable for complex working conditions in the future. An important research direction in thermal management of power lithium-ion power batteries. However, for small, short-range, and environmentally friendly electric vehicles, their thermal management intensity is relatively small, and there are still occasions for air cooling. For specific vehicle models, specific analysis is still needed to determine the most appropriate thermal management method.

We provide complete temperature control systems design and manufacturing. From standard models to complete customized products up to 900 tons. We specialize in customer service and are dedicated to helping each customer have the optimal temperature control system for their specific need.

We provide non-standard customized solutions. Both single cooling chillers and cooling & heating combo units are available.

Email: info@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

LNEYA

LNEYA

简体中文

简体中文