Data Center Liquid Cooling Solutions

What is liquid cooling?

——Using liquid instead of air as refrigerant to exchange heat for heating components and remove heat.

What is a liquid cooled server?

——A type of server that injects liquid into the server and takes away the heat dissipation of the server through cold and hot exchange.

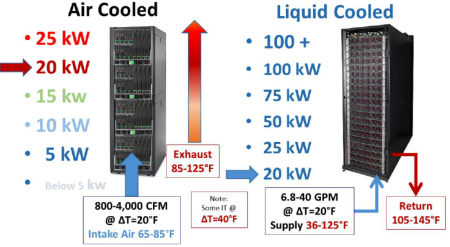

Comparison between air-cooled servers and liquid cooled servers – server heat export method is different:

1) Liquid cooling technology route

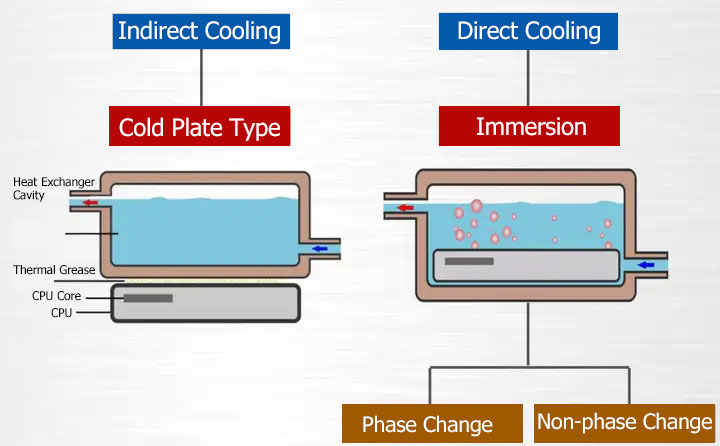

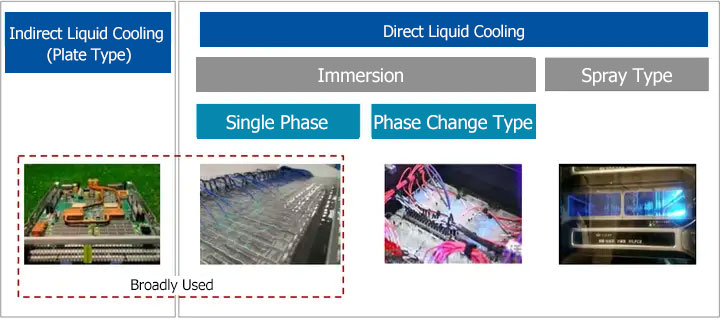

According to cooling methods, it can be divided into two categories: indirect cooling and direct cooling.

Indirect cooling mainly relies on the intermediate medium of cold plates for heat exchange of devices, which is currently widely adopted in the industry.

Direct cooling is divided into immersion and spray cooling, while immersion cooling is further divided into single-phase (non phase change) and phase change cooling, and single-phase cooling is currently widely used in the industry. Spray cooling is usually rarely used.

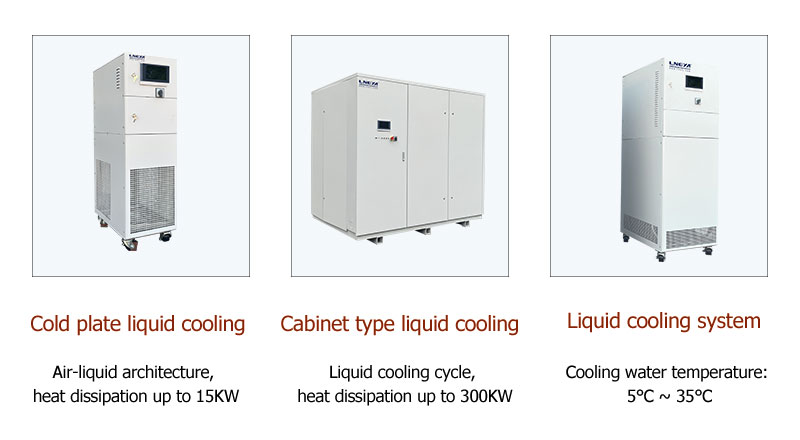

Data center cooling systems

| Model | ZLFQ-15 | ZLFQ-25 | ZLFQ-50 | ZLFQ-75 | ZLFQ-100 | ZLFQ-150 |

| Temp range | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ |

| Cooling water | 5℃~30℃ Adopt Siemens/Honeywell regulating valve to control cooling water flow | |||||

| Temperature control accuracy | ±0.2℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ |

| flow control | 10~25L/min | 25~50L/min | 40~110L/min | 70~150L/min | 150~250L/min | 200~400L/min |

| The flow control is adjusted by frequency converter, the accuracy is ±0.3L/min | ||||||

| Cooling capacity (MAX) | 15kW | 25kW | 50kW | 75kW | 100kW | 150kW |

| Storage volume | 15L | 30L | 60L | 100L | 150L | 200L |

| Brine | Water, silicone oil, fluorinated liquid, ethylene glycol aqueous solution, etc. | |||||

| Medium pipeline | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 |

| In and out interface size | G3/4 | G1 | G1 | DN32 | DN40 | DN50 |

| Cooling water interface | G3/4 | G1 | DN40 | DN50 | DN50 | DN65 |

| Cooling water flow 7~20℃ | 2.5m³/h | 4m³/h | 8m³/h | 13m³/h | 17m³/h | 25m³/h |

| 380V 50HZ | 1kW | 1.5kW | 3kW | 4kW | 5kW | 6kW |

| shell | Cold-rolled sheet spray RAL7035 | |||||

| Model | ZLFQ-200 | ZLFQ-250 | ZLFQ-300 | ZLFQ-400 | ZLFQ-500 |

| Temp range | +5℃~35℃ | ||||

| Temp accuracy | ±0.5℃ | ||||

| Flow control | 15~30m³/h | 20~35m³/h | 25~40m³/h | 30~60m³/h | 40~70m³/h |

| Cooling capacity(MAX) | 200kW | 250kW | 300kW | 400kW | 500kW |

| Storage volume | 250L | 300L | 600L | 1000L | 1200L |

| Medium | Water, silicone oil, fluorinated liquid, ethylene glycol aqueous solution, etc. | ||||

| Medium pipeline | SUS304 | ||||

| In and out interface size | DN65 | DN65 | DN65 | DN80 | DN80 |

| Cooling water interface | DN80 | DN80 | DN100 | DN100 | DN125 |

| Cooling water flow 7~20℃ | 34m³/h | 43m³/h | 51m³/h | 69m³/h | 86m³/h |

| Power supply 380V 50HZ | 7kW | 7kW | 8kW | 9kW | 13kW |

| shell | Cold-rolled sheet spray RAL7035 | ||||

We provide complete temperature control system design and manufacturing. From standard models to complete customized products. We specialize in customer service and are dedicated to helping each customer have the optimal temperature control system for their specific need.

Email: lilia@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

2) Indirect liquid cooling – cold plate type

Cold plate liquid cooling has been commercialized in the fields of HPC and AI high-density computing for over 8 years, with mature technology, complete ecology, and controllable overall costs. More importantly, the cold plate liquid cooling does not change the usage habits of customers. Components such as hard drives and optical modules are consistent with air cooling, and the operation and maintenance mode, machine room load-bearing, and air cooling scenarios are also basically the same. At the same time, the single point heat dissipation capacity is above 700 watts, which can effectively reduce data center PUE and is more suitable for large-scale commercial use.

Cold plate liquid cooling refers to a non-contact liquid cooling technology that uses liquid as the heat transfer working fluid to flow in the internal flow channel of the cold plate and cool the heat source through heat transfer. Among them, the heat is transmitted through a cold plate assembled on the electronic components that need to be cooled, and then through the heat exchange between the cold plate and the liquid working fluid, which is called non-contact liquid cooling. It is different from immersion or spray liquid cooling technology, which mainly refers to the cooling method where electronic components come into direct contact with the cooling medium.

Advantages of Cold Plate Liquid Cooling System

High heat dissipation efficiency:

1. For the main heat source CPU and memory, component level precise cooling.

2. Using liquid refrigerant, 90%+heat is taken away through liquid cooling.

3. Liquids have a large specific heat capacity, high thermal conductivity, and a heat transfer efficiency 1000 to 3000 times that of air.

Energy saving:

1. Use medium to high temperature water as the refrigerant to achieve natural cooling throughout the year, reducing energy consumption of the air conditioning system by 80%.

2. The power consumption of the air-cooled fan can be reduced by 70%.

3. The average annual PUE of the liquid cooling part is less than 1.1, and with the addition of the air cooling part, the average PUE can be optimized to 1.2.

4. Compared to traditional air cooling, the average annual electricity cost savings are 40-50%.

High performance:

1. When the server runs at full load, the CPU temperature is 40-50 ℃, which is about 30 ℃ lower than air-cooled, fully releasing the CPU overclocking performance.

2. When the server runs at full load, the memory temperature is 50-65 ℃, which is about 5-10 ℃ lower than air-cooled, making the operation more stable and reliable.

Low TCO:

The initial construction cost of liquid cooling increases by no more than 25% compared to traditional air cooling (including computer room infrastructure).

2. The system can recover the construction cost of liquid cooling after 3 years of operation.

3. The additional performance improvement brought by liquid cooling can be recouped in 2.5 years.

High stability:

1. When running at full load, the CPU temperature is 40-50 ℃, which is about 30 ℃ lower than air-cooled.

2. The system temperature is reduced by about 20 ℃ compared to air-cooled, and the stability of the device can be improved by an order of magnitude.

Low noise:

1. The water circulation noise of the liquid cooling part is extremely low.

2. The fan speed and noise of the air-cooled section decrease by about 30dB.

3. The noise level during full load operation of general liquid cooled server products is less than 60dB (at a close range of 1 meter).

Easy maintenance:

Compared to immersion liquid cooling, single unit operation and maintenance are more convenient.

3) Direct liquid cooling – immersion type

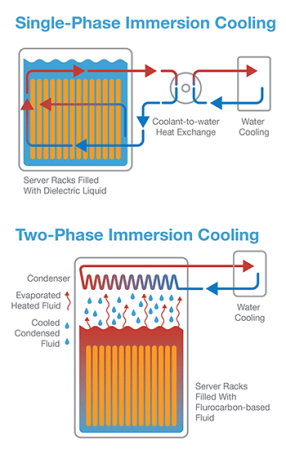

Single phase:

In a single-phase immersed liquid cooling system, all heating components of IT equipment are immersed in a circulating non-conductive coolant, and the heat emitted by the equipment is directly transferred to the coolant. Single phase immersed liquid cooled coolant typically has a high boiling point, and after absorbing heat, the coolant does not undergo phase change and remains in the liquid state.

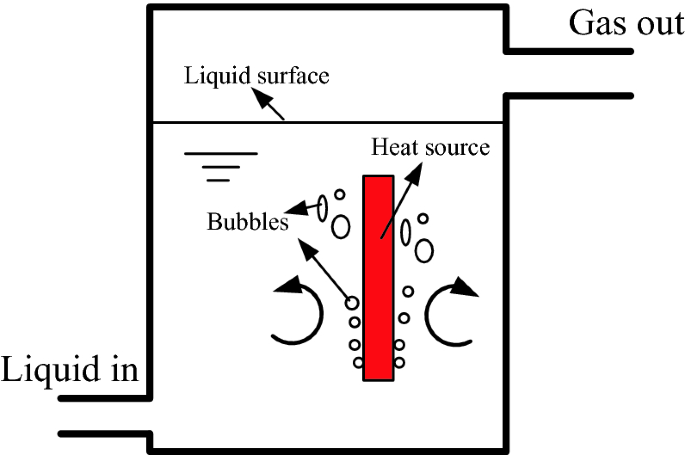

Single phase immersion liquid cooling drives the circulation of coolant through natural convection or pump driven cooling. The circulation heat dissipation process driven by natural convection takes advantage of the reduced volume expansion density of the liquid after heating. The hotter coolant will naturally float up and then be cooled by a heat exchanger connected to the external cooling circuit. The cooled liquid naturally sinks under the action of gravity, completing the cycle of heat dissipation.

Compared with natural convection, using a pump driven circulating coolant can more effectively improve cooling capacity. The device composed of a pump, heat exchanger, sensor, and filter is called a coolant distribution unit.

(CDU, CoolantDistribution Unit), using CDU can more accurately control the temperature and flow rate of the coolant. The colder coolant flows through the heating element under the drive of the pump, taking away the heat. The heated coolant enters the heat exchanger under the drive of the pump for cooling, and then continues to circulate under the action of the pump. Heat exchangers usually use water as the cooling medium, and the heat is ultimately discharged through the circulating cooling water system.

The core element of single-phase immersion liquid cooling is to immerse the complete server in the cooling liquid under charged operation. Therefore, the cooling liquid serving as the heat exchange medium must be a highly stable dielectric liquid with strong heat exchange ability but non-conductive. Such dielectric liquid is usually insoluble (or difficult to dissolve) in water medium, which can ensure its insulation is not easily damaged to the maximum extent. Its inherent characteristics in terms of odor, toxicity, difficulty in degradation, and maintainability should be as friendly to the environment and operators as possible. The most important thing is that components immersed in liquids need to be verified for compatibility and reliability with the coolant during component selection in order to provide compatibility warranty between components and coolant.

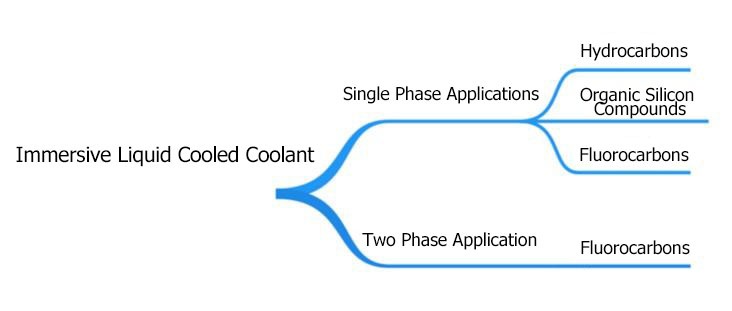

Based on the above considerations, the most widely discussed cooling liquids in the field of immersion liquid cooling are mainly divided into hydrocarbons and organosilicon compounds (oils) and fluorocarbons.

Phase change formula:

In phase change immersion liquid cooling, taking two-phase immersion liquid cooling as an example, the coolant continuously undergoes a phase change process from liquid to gas and then back to liquid during the circulating heat dissipation process. The IT equipment is completely immersed in a closed tank filled with low boiling point coolant, and the heat emitted by the equipment is absorbed by the coolant. After the coolant absorbs heat, the temperature rises, reaches the boiling point, and begins to boil, transforming from liquid to gas, while generating a large amount of steam. Steam rises from the liquid and escapes above the liquid surface, forming a gas-phase zone inside the liquid cooled tank. The cooling liquid vapor in the gas-phase zone comes into contact with the water-cooled condenser, and the heat is absorbed by the condenser. The cooling liquid condenses into a liquid and falls back into the container in the form of droplets for further circulation. The heated cooling water in the condenser is then discharged through the circulating cooling water system.

Advantages of phase change liquid cooling systems

Higher heat exchange efficiency:

1. Direct contact between refrigerant and heating device reduces contact thermal resistance.

2. Adopting phase change heat exchange, the latent heat is hundreds of times the specific heat.

More energy-efficient:

1. No fan design, reducing fan power consumption to 0.

2. Achieve natural cooling throughout the year, with a PUE value as low as 1.05.

Lower noise:

1. There is no fan inside the server, and the noise can be controlled below 45dB.

Higher reliability:

1. Solve the heat dissipation problem of all components at once.

2. Adopting full immersion method, the internal temperature field is uniform, and the reliability of the device is more guaranteed.

Higher performance:

1. The temperature of major electronic chips such as CPUs decreases and does not fluctuate with the load.

2. Improved the reliability and performance of computer hardware.

No risk of leakage:

1. Use insulated and environmentally friendly cooling liquids.

Even if a leak occurs, there is no risk to computer hardware and the external environment.

Two phase immersion liquid cooled coolant

In order to effectively utilize the phase change process of the coolant and control the temperature of IT equipment, the coolant used for two-phase immersion liquid cooling not only needs to have good thermal physical properties, chemical and thermal stability, and non corrosiveness, but also needs a suitable boiling point, a relatively narrow boiling range, and a higher latent heat of vaporization. Silicone esters, aromatic substances, organosilicon, aliphatic compounds, and fluorocarbons have all been attempted to be applied in two-phase immersion liquid cooling. Among them, fluorocarbon compounds have the best comprehensive performance and are therefore more commonly used.

Contact us today for more data center cooling solutions

Email: lilia@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

4) Direct liquid cooling – spray type

Spray type direct liquid cooling is a precise spray and direct contact liquid cooling technology for electronic devices. The coolant can be directly sprayed onto the heating components or solid thermal conductive materials connected to IT equipment through gravity or system pressure, and heat exchange can be carried out with them to achieve thermal management of IT equipment. In the process of heat exchange, the free liquid level of the coolant inside the IT equipment is lower than that of the cooled heating device or the solid thermal conductive material connected to it. The system exchanges heat with the coolant through the external heat exchange unit of the IT equipment and circulates it for use.

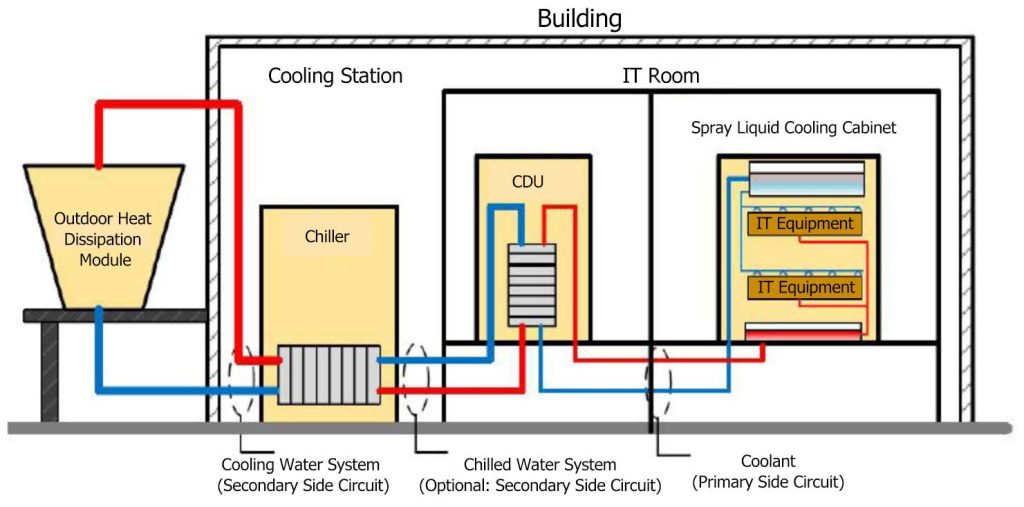

Spray type direct liquid cooling system

The following figure shows a typical schematic diagram of a spray type direct liquid cooling system, which is mainly divided into cooling water circulation, chilled water circulation, and coolant circulation. The equipment mainly consists of cooling towers, chillers, CDUs, and spray liquid cooling cabinets. The cooling cycle can be distributed or clustered, but distributed cooling solutions have higher reliability, flexibility, and scalability. In actual projects, it is recommended to distribute chilled water or cooling water to multiple CDUs, and the cooling liquid in CDUs should also be distributed to multiple cabinets. In specific engineering projects, the above circulation process and equipment are not sufficient or necessary. Based on factors such as dry bulb temperature, wet bulb temperature, building size, and supply temperature of the environment, select cooling circulation and outdoor heat dissipation modules.

Several common principles of spray direct liquid cooling systems

The principle of the first spray direct liquid cooling system

The principle of the second type of spray direct liquid cooling system

The principle of the third type of spray direct liquid cooling system

Spray type direct liquid cooling cabinet

The spray type direct liquid cooling cabinet is the core component that realizes the liquid cooling process in the entire system. Common liquid cooling standard cabinet sizes include 600mm x 1200mm x 2000mm and 600mm x 1200mm x 2200mm. The following figure shows two typical spray type liquid cooling implementation methods

The basic working principles of these two typical sprinkler cabinets are described as follows:

a) The refrigerant cooled by CDU is pumped through pipelines and transported to the interior of the cabinet;

b) After entering the cabinet, the refrigerant directly enters the distribution device corresponding to the server through the liquid distribution branch, or is transported to the storage tank to provide a fixed size of weight potential energy to drive the refrigerant to spray through the distribution device;

c) Afterwards, the refrigerant will spray and cool the heating components in IT equipment or the thermal conductive materials connected to them (such as metal radiators, VC, heat pipes, etc.) through a liquid distributor;

d) After being heated, the refrigerant will be collected through a collection device (such as a return pipe, collection box, etc.) and transported to the CDU through a pump for the next refrigeration cycle.

The main functions of CDU are achieved through the following methods

a) Supply fluid flow and pressure control: The system can be equipped with a proportional control valve in the pump outlet pipeline or perform variable frequency control on the pump to adjust the supply fluid flow or supply fluid pressure of the CDU. To improve control accuracy, the operating frequency of the pump or the opening of the proportional valve can be closed-loop controlled with pressure sensors or temperature sensors arranged on the supply pipeline;

b) Supply liquid temperature regulation: If CDU does not require flow or pressure control, the circulation pump can be set in the front section of the heat exchanger, and a proportional control valve can be installed at the pump outlet and connected to the pipeline behind the heat exchanger. The supply liquid temperature can be adjusted by controlling the proportion of flow through the heat exchanger; But a more robust approach is to adjust the temperature by adjusting the water volume of the secondary cooling loop system, which can be achieved by adding a proportional control valve or throttle valve in the secondary cooling loop system;

c) Filtering: Filtering includes filtering solid or liquid impurities (especially water) in the coolant. The filtering device (not limited to solid particle filters) can be connected in parallel or in series on the coolant circulation system pipeline;

d) Pre heating: Pre heating only requires adding a heater in the circulating equipment, but it should be noted that the surface temperature of the heater during the heating process should not be too high to avoid aging of the cooling medium.

LNEYA

LNEYA

简体中文

简体中文