Data Center Water Cooling

Contact us today for the perfect temperature control solution

Immersion liquid cooling

Immersion liquid cooling is a typical direct contact liquid cooling, which immerses the heating element in the cooling liquid and relies on the flow circulation of the liquid to take away the heat generated by the operation of IT equipment. Because the heating element is in direct contact with the coolant, immersion liquid cooling has higher heat dissipation efficiency, lower noise (no fans at all), and can solve higher heat density.

The current mainstream method is to immerse the server in a specially designed box or a custom-designed casing for the server. However, this architecture reduces the utilization of the data center building space. Without changing the existing data center deployment architecture, the casing Wrap each server with coolant.

1. Single-phase liquid cooling

It means that the coolant does not undergo phase change during the circulation and heat dissipation process and remains in a liquid state. Single-phase liquid cooling requires a high boiling point of the coolant, relatively simple control of coolant evaporation and loss, high compatibility with IT equipment components, and less contamination of the cooling medium, but its efficiency is lower than that of two-phase liquid cooling.

2. Two-phase liquid cooling

Refers to the phase change of the coolant during the circulation and heat dissipation process. Two-phase liquid cooling has higher heat transfer efficiency and does not require a pump to drive the fluid circulation. However, the control of coolant evaporation and loss is relatively complicated. Although a closed box can solve the problem of coolant evaporation and loss, it will cause the box to be damaged due to phase change. The pressure of the body changes, and the design and production of pressure vessels require strict supervision to ensure the safety of use.

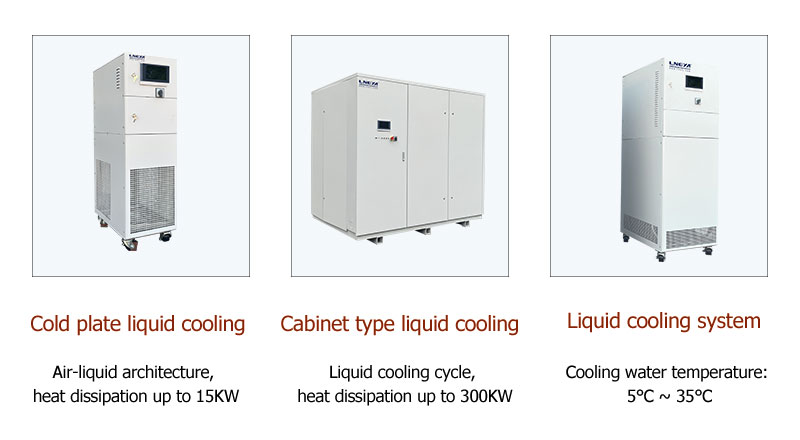

Cold plate liquid cooling

The main heating components are fixed on the cold plate, and rely on the liquid flowing through the cold plate to take away the heat for the purpose of heat dissipation. It is a typical indirect contact liquid cooling. Since other heating components such as hard drives and power supplies still require fan-driven air to dissipate heat, Servers currently using cold plate liquid cooling are also called gas-liquid dual-channel servers.

The liquid cooling of data center equipment water coolers is based on the contact between the liquid and the heating device. It is mainly used in high-performance computing in the computer and IT fields and can solve the heat dissipation problem of data centers with higher heat density.

| Model | ZLFQ-15 | ZLFQ-25 | ZLFQ-50 | ZLFQ-75 | ZLFQ-100 | ZLFQ-150 |

| Temp range | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ |

| Cooling water | 5℃~30℃ Adopt Siemens/Honeywell regulating valve to control cooling water flow | |||||

| Temperature control accuracy | ±0.2℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ |

| flow control | 10~25L/min | 25~50L/min | 40~110L/min | 70~150L/min | 150~250L/min | 200~400L/min |

| The flow control is adjusted by frequency converter, the accuracy is ±0.3L/min | ||||||

| Cooling capacity (MAX) | 15kW | 25kW | 50kW | 75kW | 100kW | 150kW |

| Storage volume | 15L | 30L | 60L | 100L | 150L | 200L |

| Brine | Water, silicone oil, fluorinated liquid, ethylene glycol aqueous solution, etc. | |||||

| Medium pipeline | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 |

| In and out interface size | G3/4 | G1 | G1 | DN32 | DN40 | DN50 |

| Cooling water interface | G3/4 | G1 | DN40 | DN50 | DN50 | DN65 |

| Cooling water flow 7~20℃ | 2.5m³/h | 4m³/h | 8m³/h | 13m³/h | 17m³/h | 25m³/h |

| 380V 50HZ | 1kW | 1.5kW | 3kW | 4kW | 5kW | 6kW |

| shell | Cold-rolled sheet spray RAL7035 | |||||

| Model | ZLFQ-200 | ZLFQ-250 | ZLFQ-300 | ZLFQ-400 | ZLFQ-500 |

| Temp range | +5℃~35℃ | ||||

| Temp accuracy | ±0.5℃ | ||||

| Flow control | 15~30m³/h | 20~35m³/h | 25~40m³/h | 30~60m³/h | 40~70m³/h |

| Cooling capacity(MAX) | 200kW | 250kW | 300kW | 400kW | 500kW |

| Storage volume | 250L | 300L | 600L | 1000L | 1200L |

| Medium | Water, silicone oil, fluorinated liquid, ethylene glycol aqueous solution, etc. | ||||

| Medium pipeline | SUS304 | ||||

| In and out interface size | DN65 | DN65 | DN65 | DN80 | DN80 |

| Cooling water interface | DN80 | DN80 | DN100 | DN100 | DN125 |

| Cooling water flow 7~20℃ | 34m³/h | 43m³/h | 51m³/h | 69m³/h | 86m³/h |

| Power supply 380V 50HZ | 7kW | 7kW | 8kW | 9kW | 13kW |

| shell | Cold-rolled sheet spray RAL7035 | ||||

We provide complete temperature control system design and manufacturing. From standard models to complete customized products up to 1000 tons. We specialize in customer service and are dedicated to helping each customer have the optimal temperature control system for their specific need.

We provide non-standard customized solutions.

Email: info@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

LNEYA

LNEYA

简体中文

简体中文