Battery Pack Thermal Management

Kontaktieren Sie uns noch heute für die perfekte Lösung zur Temperaturkontrolle

What is thermal management?

Thermal management, in short, is a process in which components such as batteries use heating or cooling and other related methods to adjust and control the temperature and temperature difference of the target object. The basic principles involved include three heat transfer processes: heat conduction, convective heat transfer or thermal radiation, and these three processes all involve temperature differences, so the thermal management process consumes energy to create a temperature difference between the target object and the external environment.

There are many application scenarios, and it has been widely used in industry, communications industry, consumer electronics, servers, energy storage, new energy vehicles and other scenarios. It has a very positive effect on the normal and stable operation of related equipment or electronic components. With the With the rapid development of related industries, the thermal management industry will also receive more and more attention.

The importance of thermal management

1. Thermal management can prevent overheating and system failures. With the rapid development of thermal management-related application scenarios, the functions of related equipment have increased, and the work of components has accumulated a large amount of heat. Excessive heat accumulation will cause damage to electronic components, reduced device performance, and even the collapse of the entire system. Through reasonable thermal management measures, heat can be effectively dissipated to ensure that the system operates within an appropriate temperature range and improve system reliability.

2. Through thermal management, the performance and service life of the equipment can be greatly enhanced. Taking currently commonly used mobile phones as an example, since the internal structure of the mobile phone is quite compact, there are basically few gaps between various electronic components. If the heat from the battery and processor cannot be discharged in time, it will affect the various temperatures of other components, thereby breaking the coordination of each hardware, which will not only affect the performance of the device but also the service life of the mobile phone.

3. From the perspective of safety necessity. Thermal management systems are indispensable in related industries. Taking the energy storage industry as an example, as the scale of energy storage power stations increases, the number and power of batteries increase, a large amount of heat will accumulate during operation. If the heat cannot be dissipated effectively and timely, the It will cause serious consequences of thermal runaway. Therefore, effective thermal management is of great significance to safety.

4. Thermal management can improve energy utilization. In new energy vehicles, too high or too low working environment will affect the performance of the battery, thus affecting the cruising range of new energy vehicles. Through reasonable and effective thermal management strategies, the operating temperature can be maintained at a reasonable temperature, energy consumption can be reduced, and operating costs can be reduced.

In summary, thermal management is important in terms of preventing overheating and system failure, enhanced performance and longevity, safety considerations, and energy efficiency and cost savings.

Application areas of thermal management

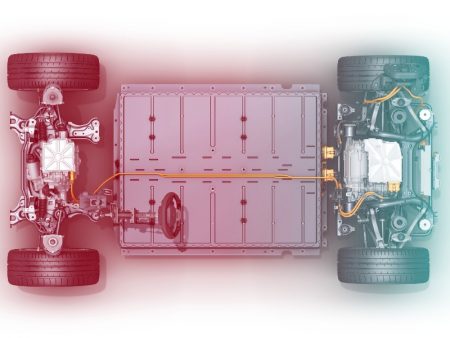

The thermal management industry currently has many applications in the power battery industry and energy storage industry. In the field of power batteries, the thermal management of new energy vehicles is growing rapidly. As the penetration rate of new energy vehicles into the market increases and the performance of related products upgrades, the thermal management system has huge market space and value in new energy.

Thermal management has multiple meanings for new energy vehicles. First of all, the cruising range of new energy vehicles is one of the indicators that consumers are very concerned about. The thermal management system can effectively control the battery temperature, prevent battery packs and battery performance degradation caused by overheating and overcooling, and improve Battery usage efficiency extends the vehicle’s cruising range.

Secondly, the safety of power batteries can be enhanced. Power batteries are the power source and important component of new energy vehicles. The thermal management system can effectively control the operating temperature through the BMS system, prevent fires and other accidents caused by thermal runaway, and ensure the safety of vehicles and passengers. Safety. Moreover, with the development of the new energy vehicle industry, relevant departments have increasingly higher requirements for the safety performance and quality of complete vehicles. Relevant laws and regulations also require car companies to have corresponding thermal management capabilities to ensure the safety and quality of complete vehicles. .

Types of Thermal Management Technologies

Taking the field of electric vehicles as an example, current thermal management solutions can be roughly divided into four types: air cooling, liquid cooling, direct cooling, and phase change materials.

1. Air cooling is a common and simple method of heat dissipation, using natural airflow or fans to blow away the heat absorbed by the radiator. It has the advantages of low cost, simple installation, reliability and easy maintenance, but it is greatly affected by the environment and was mostly used in early electric vehicles.

2. Liquid cooling can be divided into cold plate liquid cooling and immersion liquid cooling. Cold plate liquid cooling is an indirect heat dissipation method. By contacting the cooling plate with the battery, the coolant in the cold plate is used to exchange heat with the battery, and Heat is removed through cooling channels. Immersion liquid cooling is a cooling method that immerses the battery module in an insulating cooling liquid to perform heat exchange. Liquid cooling has the advantages of high heat exchange efficiency and uniform heat, but the cost is higher.

3. Direct refrigerant cooling uses the refrigerant from the vehicle air conditioning system to directly flow the refrigerant into the evaporator inside the battery. The refrigerant evaporates in the evaporator and efficiently takes away the heat from the battery system. This design is simple and easy to disassemble, with low subsequent maintenance costs. However, direct heating is not possible and additional heating systems need to be added.

4. Phase change materials can be divided into three types: inorganic phase change materials, organic phase change materials and composite phase change materials. Its heat absorption and release process makes the system temperature stable and can achieve a nearly constant temperature effect. It has been applied in many fields. It has simple structure, small mass and huge latent heat characteristics, but the replacement cost is high and the stability is poor.

Zusammenfassend

Thermal management With the development of related industries, relevant departments have paid more and more attention to energy consumption and safety, and customers’ demand for the stability of related products has been increasingly valued by manufacturers. Its features in maintaining system stability, enhancing performance, enhancing security and reducing costs are also favored by relevant industry insiders. Therefore, with the continuous development of related material technologies, more and more solutions will be applied, and the application scenarios of thermal management will be further expanded.

Wir bieten die Entwicklung und Herstellung kompletter Temperaturkontrollsysteme an. Von Standardmodellen bis zu kompletten kundenspezifischen Produkten bis hin zu 900 Tonnen. Wir haben uns auf den Kundenservice spezialisiert und sind bestrebt, jedem Kunden zu helfen, das optimale Temperaturkontrollsystem für seinen spezifischen Bedarf zu finden.

Wir bieten maßgeschneiderte Lösungen, die nicht dem Standard entsprechen. Es sind sowohl einzelne Kühlaggregate als auch kombinierte Kühl- und Heizaggregate erhältlich.

E-Mail: info@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

LNEYA

LNEYA

简体中文

简体中文