Cold Plate Cooling Solution for Data Center

Kontaktieren Sie uns noch heute für die perfekte Lösung zur Temperaturkontrolle

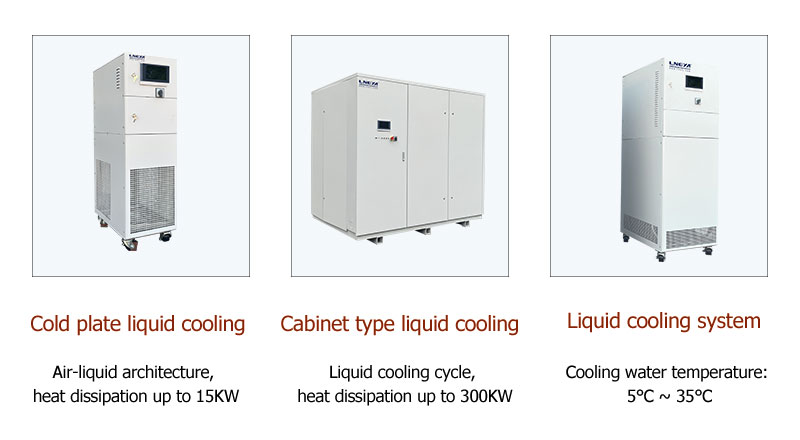

Cold plate liquid cooling refers to a non-contact liquid cooling technology that uses liquid as a heat transfer medium to flow in the internal flow channels of the cold plate and cool the heat source through heat transfer. In a cold plate liquid cooling system, heat-generating devices such as server chips do not directly contact the liquid, but dissipate heat through a cold plate installed on the electronic components that need to be cooled. Therefore, this method requires less changes to existing server chip components and ancillary components and is more operable. It has become the most mature and widely used liquid cooling solution at present.

Among them, the cold plate liquid cooling primary side cooling source can use mechanical refrigeration system and natural cooling system. The mechanical refrigeration system includes air-cooled chilled water system and water-cooled chilled water system, which can provide medium-temperature chilled water between 12C and 18℃. Natural cooling is a cooling process that uses the cooling capacity of outdoor air without mechanical refrigeration when outdoor meteorological conditions permit. The natural cooling system can be implemented by open cooling towers, closed cooling towers, dry coolers and other equipment, and can provide Cooling water above 30C. The form of the liquid-cooled primary side cooling source must be determined based on the secondary side terminal water temperature requirements and the outdoor environmental conditions of the project site.

1. Mechanical refrigeration system

Air-cooled chilled water system

The air-cooled chilled water system is a way of preparing chilled water. It is mainly composed of an air-cooled chiller, a chilled water pump and supporting facilities. Its liquid refrigerant evaporates directly in its evaporator coil to realize the absorption of chilled water outside the coil. Hot and cool, and cooled to a liquid state by air cooling.

The air-cooled chilled water system does not require a dedicated machine room and does not require the installation of cooling towers and pump rooms. It has low initial cost, is easy to operate, does not require professional maintenance, has no cooling water system, and has the advantages of saving water and reducing maintenance costs. However, air-cooled chillers are generally installed outdoors, and the operation and maintenance environment is relatively harsh. Maintenance and reliability are not as good as water-cooled chillers. Moreover, air-cooled chillers have poor cooling effect at high temperatures in summer and low operating efficiency.

Water-cooled chilled water system

The water-cooled chilled water system is a way of preparing chilled water. It is mainly composed of water-cooled chillers, chilled water pumps, cooling water pumps, cooling towers and supporting facilities. The liquid refrigerant evaporates directly in the evaporator coil to achieve external cooling of the coil. Frozen water absorbs heat to cool, and is cooled into a liquid state through water cooling.

The water-cooled chilled water system has the advantages of low power consumption, good cooling effect all year round, high reliability and long service life. However, it requires a dedicated machine room, cooling tower, cooling water pump, chilled water pump and other equipment, the initial investment is large, and it requires circulating water, which consumes a lot of water resources, and the unit body and cooling facilities require maintenance. Compared with air-cooled units, their maintenance is The cost is relatively high.

2. Natural cooling system

Open cooling tower

The open cooling tower sprays the circulating cooling water directly onto the cooling tower filler. At the same time, the fan drives the air flow in the cooling tower. The circulating water is evaporated and cooled through the heat and mass exchange between the outdoor air and the cooling water. The cooled circulating water Water exits at the bottom of the cooling tower (see Figure 2). There is heat and mass exchange between circulating cooling water and outdoor air in an open cooling tower.

Open cooling towers have lower initial investment and operating costs, smaller floor space, and lighter weight. However, their operating water quality is poor and can easily cause scaling of the heat exchangers being cooled. They are suitable for areas with good outdoor air quality. In addition, although a first-stage plate heat exchanger and cooling water pump can be added to avoid scaling of the core heat exchanger, the corresponding system is more complex and the initial investment increases.

Closed cooling tower

A closed cooling tower is a device that places a tubular heat exchanger inside the tower and dissipates heat to the atmosphere through heat exchange between outdoor circulating air, spray water and circulating cooling water in the tube (see Figure 3). The closed cooling tower has two systems: internal circulation and external circulation. The internal circulation is connected with the equipment to be cooled to form a closed system, which brings the system heat to the cooling tower. That is, the internal circulation water transfers the heat through the heat exchange coil. Passed to the atmosphere; the external circulation is composed of a circulating spray pump, a water distribution system, a water collecting tray and pipelines. The external circulation water does not contact the internal circulation water, but only absorbs the internal circulation water through the heat exchanger in the cooling tower. The heat is then dissipated through direct contact with the air.

The water quality of the closed cooling tower is good, the cooled heat exchanger is not easy to scale, and has a long service life. It has obvious advantages in applications where the outdoor environment quality is poor and the circulating water quality is high. However, the initial investment and operating costs of the closed cooling tower are relatively high. It is tall, covers a large area and is heavy.

Dry cooler

Dry cooler is a dry cooler. There is no consumption of water in its working process. It cools the liquid in the tube through the liquid inside the tube and the natural air outside the tube, reducing the temperature of the liquid in the tube to achieve the purpose of cooling.

The dry cooler does not have a compressor, has low overall power consumption, long service life of the unit, and lower initial investment than air-cooled cold water systems and water-cooled cold water systems. However, it is generally installed outdoors, and the operating environment is relatively harsh, and heat dissipation is poor in hot summer weather. In this area, a water spray cooling system or wet curtain system needs to be configured to enhance heat exchange, resulting in an increase in floor space.

Primary side system application scenarios

In a cold plate liquid cooling system, the heating device does not directly contact the liquid, but dissipates heat through direct contact with the cold plate containing the liquid, or the heat is conducted to the cold plate by a thermally conductive component, and then circulates through the liquid inside the cold plate. Take the heat. Since heating devices such as server chips do not need to be in direct contact with liquid, this method requires less changes to existing server chip components and ancillary components and is more operable, making it a highly mature and widely used liquid cooling solution.

The secondary side is relatively stable and is configured through the coolant distribution unit (CDU) and subsequent system architecture. The primary side can be combined considering a variety of usage conditions and scenarios.

The secondary side liquid loop refers to the design from the cooling distribution unit to the rack, connected to the IT equipment through the supply and return cooling fluid manifold, and then returned to the cooling distribution unit through the manifold. The heat from the secondary cooling circuit is transferred to the primary cooling circuit through the plate heat exchanger of the cooling distribution unit, and is eventually discharged to the atmosphere or recovered and reused.

As the power density of IT equipment increases, more efficient cooling technologies are needed to meet the growing demand for computing power. Compared with traditional air cooling, the liquid cooling solution provides more efficient cooling efficiency. When to switch to liquid cooling depends on many different factors, including cooling performance needs, power configuration, PUE requirements, IT equipment density, cooling costs, as well as future IT equipment performance needs and deployment strategies. In addition, whether to renovate existing facilities or build a new data center computer room also needs to be taken into consideration in terms of TCO.

A direct reason for using liquid cooling is that traditional air cooling solutions can no longer meet the cooling needs of IT equipment, so new solutions are needed to improve cooling capabilities. There are no general guidelines for when or at what power levels liquid cooling is required for power-hungry components such as CPUs and GPUs. However, it should be noted that in addition to cost analysis, there are also some design considerations for liquid cooling solutions that need to be understood, such as whether all wetted materials in the cooling circuit are compatible with the cooling fluid used and maintain long-term reliability, and the cooling fluid used It cannot be mixed with any other cooling fluid, etc.

| Modell | ZLFQ-15 | ZLFQ-25 | ZLFQ-50 | ZLFQ-75 | ZLFQ-100 | ZLFQ-150 |

| Temperaturbereich | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ |

| Kühlwasser | 5℃~30℃ Einsatz eines Siemens/Honeywell-Regelventils zur Steuerung des Kühlwasserflusses | |||||

| Genauigkeit der Temperaturregelung | ±0.2℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ |

| Flusskontrolle | 10~25L/min | 25~50L/min | 40~110L/min | 70~150L/min | 150~250L/min | 200~400L/min |

| Die Durchflussregelung wird über einen Frequenzumrichter eingestellt, die Genauigkeit beträgt ±0,3 l/min. | ||||||

| Kühlleistung (MAX) | 15kW | 25kW | 50kW | 75kW | 100kW | 150kW |

| Speichervolumen | 15L | 30L | 60L | 100L | 150L | 200L |

| Sole | Wasser, Silikonöl, fluorierte Flüssigkeit, wässrige Ethylenglykol-Lösung, usw. | |||||

| Mittlere Rohrleitung | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 |

| Größe der Eingangs- und Ausgangsschnittstelle | G3/4 | G1 | G1 | DN32 | DN40 | DN50 |

| Schnittstelle zum Kühlwasser | G3/4 | G1 | DN40 | DN50 | DN50 | DN65 |

| Kühlwasserdurchfluss 7~20℃ | 2.5m³/h | 4m³/h | 8m³/h | 13m³/h | 17m³/h | 25m³/h |

| 380V 50HZ | 1kW | 1,5 kW | 3kW | 4kW | 5kW | 6kW |

| Shell | Kaltgewalztes Blech Spray RAL7035 | |||||

| Modell | ZLFQ-200 | ZLFQ-250 | ZLFQ-300 | ZLFQ-400 | ZLFQ-500 |

| Temperaturbereich | +5℃~35℃ | ||||

| Temperaturgenauigkeit | ±0.5℃ | ||||

| Durchflusskontrolle | 15~30m³/h | 20~35m³/h | 25~40m³/h | 30~60m³/h | 40~70m³/h |

| Kühlleistung(MAX) | 200kW | 250kW | 300kW | 400kW | 500kW |

| Speichervolumen | 250L | 300L | 600L | 1000L | 1200L |

| Mittel | Wasser, Silikonöl, fluorierte Flüssigkeit, wässrige Ethylenglykol-Lösung, usw. | ||||

| Mittlere Rohrleitung | SUS304 | ||||

| Größe der Eingangs- und Ausgangsschnittstelle | DN65 | DN65 | DN65 | DN80 | DN80 |

| Schnittstelle zum Kühlwasser | DN80 | DN80 | DN100 | DN100 | DN125 |

| Kühlwasserdurchfluss 7~20℃ | 34m³/h | 43m³/h | 51m³/h | 69m³/h | 86m³/h |

| Stromversorgung 380V 50HZ | 7kW | 7kW | 8kW | 9kW | 13kW |

| Shell | Kaltgewalztes Blech Spray RAL7035 | ||||

Wir bieten die Entwicklung und Herstellung kompletter Temperaturkontrollsysteme an. Von Standardmodellen bis zu kompletten kundenspezifischen Produkten bis hin zu 1000 Tonnen. Wir haben uns auf den Kundenservice spezialisiert und sind bestrebt, jedem Kunden zu helfen, das optimale Temperaturkontrollsystem für seinen spezifischen Bedarf zu finden.

Wir bieten maßgeschneiderte Lösungen, die nicht dem Standard entsprechen.

E-Mail: lilia@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

LNEYA

LNEYA

简体中文

简体中文