Data Center Cooling System Types

Kontaktieren Sie uns noch heute für die perfekte Lösung zur Temperaturkontrolle

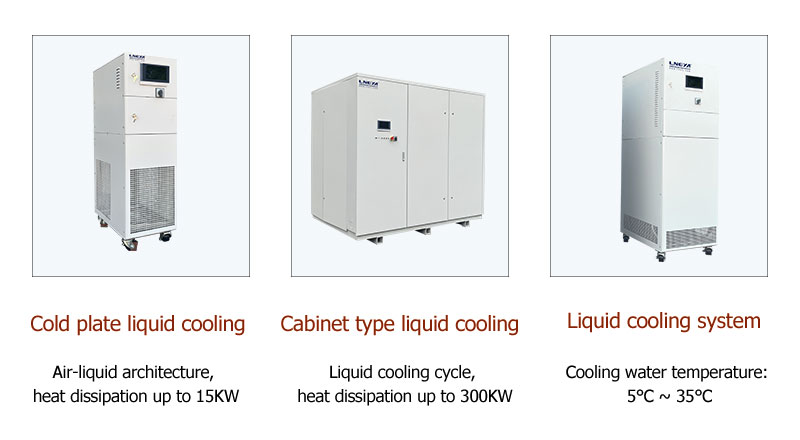

From the perspective of cooling methods, there are two main cooling methods for data center computer rooms: air cooling and liquid cooling. The cooling capacity of liquid cooling is 1,000 to 3,000 times that of air, and liquid cooling has low environmental requirements and strong adaptability. Liquid cooling is mainly divided into immersion liquid cooling and cold plate liquid cooling. In addition, what other cooling methods are used in the data center computer room?

1. The first type is traditional water-cooled or air-cooled chiller refrigeration. Air cooling, water cooling, air-liquid hybrid and cold plate liquid cooling solutions are very mature, and the immersed solution is more efficient, green and energy-saving.

The increase in chip computing power has brought about an increase in the difficulty of heat dissipation for a single chip. As the upper limit of air cooling solution capabilities approaches, it will be difficult to solve the heat dissipation problem with air cooling alone in the future.

The deployment cost of immersed liquid cooling is high, several times that of traditional data center cooling modes. It is currently mainly used in intelligent computing centers or ultra-large data centers of leading customers. In the next two to three years, it is expected to gradually be implemented in the Internet, telecommunications, finance, and manufacturing industries. Large-scale development will also go through a long process.

2. The second type is natural cooling source combined with traditional refrigeration system. This system is generally suitable for cold areas and has absolute advantages in meeting the temperature environment requirements of data center rooms.

3. The third type is fluorinated liquid immersion refrigeration. Using the 50°C boiling point characteristics of fluorinated liquid, phase change refrigeration is used to cool the CPU, and then condensation, liquefaction and reflux are used. The current test results are good. The advantage of this method is that the unit heat flux density of the phase change of the fluorinated liquid is large, which can satisfy the fan heating of the CPU with high heat flux density. In addition, some units use fluorinated liquid as a cooling system, which circulates and cools the fluorinated liquid on the basis of soaking. The heat exchange is between convection and supercooled boiling, and the heat transfer efficiency is also high. This solution requires a large amount of fluorinated liquid and the initial investment cost is high.

4. The fourth type is evaporative refrigeration. This system mainly absorbs heat and refrigeration through the evaporation of water vapor, without the need for compressor compression. The electricity load of the system is low, and the PUE can reach 1.1. However, this solution is greatly affected by the weather and is more suitable for places with low humidity and temperature, which is affected by geographical location. In addition, the refrigeration equipment is larger and requires higher investment.

5. The fifth type is absorption refrigeration. This method mainly uses waste heat for cooling, but the temperature of the heat source has a great influence on the cooling efficiency. The heat source recovered in the data center is at 50°C, so the efficiency of absorption refrigeration is very low and technically difficult. If there is a waste heat source with a higher temperature of 90℃ or above near the data center, this method is more energy-saving. This type of refrigeration solution is currently rarely used, and most scientific research institutions are still exploring absorbing materials and reducing the temperature of the recovered heat source.

6. The sixth method is to use direct cooling system for refrigeration. Freon is currently subject to restrictions due to its double carbon. The transcritical cycle or supercritical cycle of carbon dioxide can be used, but more scholars need to apply and develop it.

| Modell | ZLFQ-15 | ZLFQ-25 | ZLFQ-50 | ZLFQ-75 | ZLFQ-100 | ZLFQ-150 |

| Temperaturbereich | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ |

| Kühlwasser | 5℃~30℃ Einsatz eines Siemens/Honeywell-Regelventils zur Steuerung des Kühlwasserflusses | |||||

| Genauigkeit der Temperaturregelung | ±0.2℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ |

| Flusskontrolle | 10~25L/min | 25~50L/min | 40~110L/min | 70~150L/min | 150~250L/min | 200~400L/min |

| Die Durchflussregelung wird über einen Frequenzumrichter eingestellt, die Genauigkeit beträgt ±0,3 l/min. | ||||||

| Kühlleistung (MAX) | 15kW | 25kW | 50kW | 75kW | 100kW | 150kW |

| Speichervolumen | 15L | 30L | 60L | 100L | 150L | 200L |

| Sole | Wasser, Silikonöl, fluorierte Flüssigkeit, wässrige Ethylenglykol-Lösung, usw. | |||||

| Mittlere Rohrleitung | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 |

| Größe der Eingangs- und Ausgangsschnittstelle | G3/4 | G1 | G1 | DN32 | DN40 | DN50 |

| Schnittstelle zum Kühlwasser | G3/4 | G1 | DN40 | DN50 | DN50 | DN65 |

| Kühlwasserdurchfluss 7~20℃ | 2.5m³/h | 4m³/h | 8m³/h | 13m³/h | 17m³/h | 25m³/h |

| 380V 50HZ | 1kW | 1,5 kW | 3kW | 4kW | 5kW | 6kW |

| Shell | Kaltgewalztes Blech Spray RAL7035 | |||||

| Modell | ZLFQ-200 | ZLFQ-250 | ZLFQ-300 | ZLFQ-400 | ZLFQ-500 |

| Temperaturbereich | +5℃~35℃ | ||||

| Temperaturgenauigkeit | ±0.5℃ | ||||

| Durchflusskontrolle | 15~30m³/h | 20~35m³/h | 25~40m³/h | 30~60m³/h | 40~70m³/h |

| Kühlleistung(MAX) | 200kW | 250kW | 300kW | 400kW | 500kW |

| Speichervolumen | 250L | 300L | 600L | 1000L | 1200L |

| Mittel | Wasser, Silikonöl, fluorierte Flüssigkeit, wässrige Ethylenglykol-Lösung, usw. | ||||

| Mittlere Rohrleitung | SUS304 | ||||

| Größe der Eingangs- und Ausgangsschnittstelle | DN65 | DN65 | DN65 | DN80 | DN80 |

| Schnittstelle zum Kühlwasser | DN80 | DN80 | DN100 | DN100 | DN125 |

| Kühlwasserdurchfluss 7~20℃ | 34m³/h | 43m³/h | 51m³/h | 69m³/h | 86m³/h |

| Stromversorgung 380V 50HZ | 7kW | 7kW | 8kW | 9kW | 13kW |

| Shell | Kaltgewalztes Blech Spray RAL7035 | ||||

Wir bieten die Entwicklung und Herstellung kompletter Temperaturkontrollsysteme an. Von Standardmodellen bis zu kompletten kundenspezifischen Produkten bis hin zu 1000 Tonnen. Wir haben uns auf den Kundenservice spezialisiert und sind bestrebt, jedem Kunden zu helfen, das optimale Temperaturkontrollsystem für seinen spezifischen Bedarf zu finden.

Wir bieten maßgeschneiderte Lösungen, die nicht dem Standard entsprechen.

E-Mail: lilia@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

LNEYA

LNEYA

简体中文

简体中文