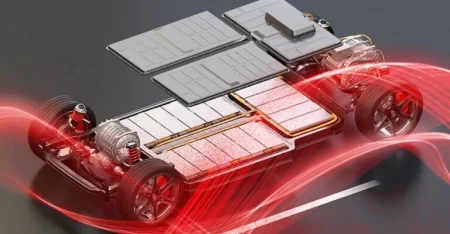

Water Cooling Battery

Kontaktieren Sie uns noch heute für die perfekte Lösung zur Temperaturkontrolle

If new energy vehicles cannot take away heat in time during driving, it will inevitably affect the performance and service life of the battery, and may even cause major hidden dangers to driving safety. For lithium-ion batteries, high temperatures accelerate the aging of power battery cells, separators and other components. At the same time, temperature imbalance will increase the physical property differences between battery packs, thereby destroying the consistency between batteries, causing performance mismatch between individual cells, and ultimately causing the entire battery pack to fail prematurely. When the temperature is too low for charging, lithium ions will be reduced to metallic lithium dendrites, which can easily pierce the internal separator of the battery and cause an internal short circuit in the tram, posing a safety hazard. Therefore, effective battery pack thermal management (BTM) is an indispensable task for hybrid electric vehicles (HEV) under different environmental conditions and working conditions. It is also the guarantee for good cycle life and safe operation of power batteries.

Thermal management method of battery pack water cooling system The thermal management of power battery can be divided into thermal management of cooling process and thermal management of heating process. Warming thermal management is to increase the temperature of the battery box when the ambient temperature of the battery is too low, so that the active materials in the battery can exert their effects and improve battery utilization. The main battery heating methods include external hot gas heating, heating wire heating, heating plate heating, heating film heating, etc. Due to the low thermal conductivity of gas, the heating effect is not obvious: heating methods such as heating wires and heating films commonly cause temperature imbalance within the battery pack.

Currently, the most commonly used thermal management methods include forced air cooling, liquid cooling, phase change material cooling, etc. The forced air cooling method uses air as the cooling medium and is driven by a fan to cool the battery pack. The temperature difference within the battery module has a great relationship with the layout and ventilation method of the battery pack. Generally speaking, the heat dissipation conditions of the batteries at the edges of the battery pack are relatively good, while the batteries in the middle are prone to accumulating heat, and the thermal balance of the battery pack is relatively poor.

The liquid cooling method of the battery pack water cooling system uses liquid as the heat transfer medium and is equipped with a coolant pump and a heat exchanger. Liquid cooling is divided into two types: direct contact cooling and indirect contact cooling. For non-direct contact heat transfer (such as heat transfer tubes, jackets, etc.), the heat transfer medium can be water, ethylene glycol, etc. For direct contact heat transfer, mineral oil can be used as the heat transfer medium. The rate of heat transfer between the module and the heat transfer medium depends on the thermal conductivity, viscosity, density and flow rate of the liquid. Therefore, when selecting the heat transfer medium, try to choose a fluid with high thermal conductivity and good fluidity.

The phase change cooling method uses phase change materials for heat transfer and uses the state changes of the phase change materials to absorb the heat emitted by the batteries. This method requires filling phase change materials between the batteries, which will increase the overall mass and the more filling. The tighter the battery, the more heat is exchanged, which makes it difficult to assemble the battery box. It also causes unnecessary trouble due to phase change coverage during debugging and maintenance of the battery box.

Wir bieten die Entwicklung und Herstellung kompletter Temperaturkontrollsysteme an. Von Standardmodellen bis zu kompletten kundenspezifischen Produkten bis hin zu 900 Tonnen. Wir haben uns auf den Kundenservice spezialisiert und sind bestrebt, jedem Kunden zu helfen, das optimale Temperaturkontrollsystem für seinen spezifischen Bedarf zu finden.

Wir bieten maßgeschneiderte Lösungen, die nicht dem Standard entsprechen. Es sind sowohl einzelne Kühlaggregate als auch kombinierte Kühl- und Heizaggregate erhältlich.

E-Mail: info@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

LNEYA

LNEYA

简体中文

简体中文