Cooling Water Circulation Chiller

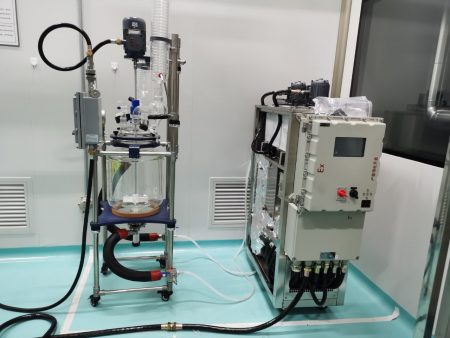

The cooling water circulation chiller is an important industrial equipment used to control and maintain the temperature in industrial processes. They work similarly to air conditioning systems but are primarily used to cool industrial equipment and processes.

The cooling water circulation chiller is one of the indispensable equipment in modern industry. Their main task is to remove heat from industrial equipment and processes to ensure the equipment operates properly and maintains a stable operating temperature. This is critical for many industrial applications, as excessive temperatures can lead to equipment failure and reduced productivity.

How does cooling water circulation chiller work?

The working principle of cooling water circulation chiller is to absorb heat from the object being cooled and discharge it to the surrounding environment through the processes of compression, condensation, expansion and evaporation of the refrigerant in the refrigeration system, thereby achieving cooling of the object being cooled. .

Specifically, cooling water circulation chiller mainly consists of compressor, condenser, expansion valve, evaporator and other parts. During operation, the refrigerant enters the evaporator after being cooled by the condenser and throttled by the expansion valve under the action of the compressor, absorbing the heat in the object being cooled and taking it away. Then, the refrigerant is compressed and condensed again under the action of the compressor, forming a cycle, thereby achieving continuous cooling of the object being cooled.

One of the key advantages of cooling water circulation chillers is that they can be customized to suit the needs of different industrial applications. Different processes require different temperatures and cooling rates, so the cooling system needs to be adjusted and optimized according to the specific conditions. This flexibility has made cooling water circulation chillers an important part of a variety of industrial sectors, with applications ranging from manufacturing to the chemical industry.

Applications of cooling water circulation chiller

Cooling water circulation chiller is widely used in industrial production processes, such as: Plastic industry: accurately controls the mold temperature of various plastic processing, shortens the beer molding cycle, and ensures the stability of product quality.

Electronic industry: Stabilize the molecular structure of electronic components on the production line, improve the qualification rate of electronic components, and be used in the ultrasonic cleaning industry to effectively prevent the volatilization of expensive cleaning agents and the harm caused by volatilization.

Electroplating industry: control the electroplating temperature, increase the density and smoothness of plated parts, shorten the electroplating cycle, increase production efficiency, and improve product quality.

Machinery industry: Control the temperature of the pressure oil in the hydraulic system, stabilize the oil temperature and oil pressure, extend the service life of the oil, improve the efficiency of mechanical lubrication, and reduce wear.

Construction industry: Supply chilled water for concrete to make the molecular structure of concrete suitable for construction purposes and effectively enhance the hardness and toughness of concrete.

Vacuum coating: Control the temperature of the vacuum coating machine to ensure the quality of the plated parts.

Food industry: used for rapid cooling after food processing to adapt to packaging requirements. There are also controls on the temperature of fermented foods.

Chemical fiber industry: Freeze drying air to ensure product quality.

Ofrecemos diseño y fabricación de sistemas completos de control de temperatura. Desde modelos estándar hasta productos personalizados completos de hasta 900 toneladas. Nos especializamos en el servicio al cliente y nos dedicamos a ayudar a cada cliente a tener el sistema de control de temperatura óptimo para su necesidad específica.

Ofrecemos soluciones personalizadas no estándar. Disponemos tanto de enfriadoras individuales como de unidades combinadas de refrigeración y calefacción.

Correo electrónico: info@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

Enfriadoras de recirculación / Criotermostatos

El enfriador puede utilizarse ampliamente en diversas industrias y laboratorios, y admite diseños personalizados.

| Temperatura | Serie -25°C ~ +30°C | Serie -45°C ~ +30°C | Serie -60°C ~ -20°C | Serie -80°C ~ -20°C | Serie -120°C ~ -70°C | ||||

| Capacidad de refrigeración | 0,8 ~ 30 kW | 0,75 ~ 12 kW | 0,4 ~ 6kW | 0,2 ~ 6kW | 0,3 ~ 5kW | ||||

| Nota: Se puede personalizar cualquier rango de temperatura de -150℃ ~ +350℃ y cualquier capacidad de refrigeración. | |||||||||

Enfriadoras de agua / Enfriadoras pequeñas

Enfriadoras de agua / Enfriadoras pequeñas

El enfriador puede utilizarse ampliamente en diversas industrias y laboratorios, y admite diseños personalizados.

| Temperatura | -18°C ~ +30°C | Serie +5°C ~ +35°C | |||||||

| Capacidad de refrigeración | 0,35 ~ 0,9 kW | 1,8 ~ 50 kW | |||||||

| Nota: Se puede personalizar cualquier rango de temperatura de -150℃ ~ +350℃ y cualquier capacidad de refrigeración. | |||||||||

Refrigeradores de baja temperatura

Estamos especializados en la producción de refrigeradores de baja temperatura con un rango de control de temperatura de hasta -150°C, que pueden satisfacer las necesidades de refrigeración de diferentes industrias.

| Temperatura | Serie -25°C ~ -5°C | Serie -45°C ~ -10°C | Serie -60°C ~ -10°C | Serie -80°C ~ -30°C | Serie -110°C ~ -50°C | Serie -150°C ~ -110°C | |||

| Capacidad de refrigeración | 12 ~ 360 kW | 6 ~ 180 kW | 6 ~ 180 kW | 4 ~ 180kW | 2 ~ 120kW | 2,5 ~ 11 kW | |||

| Nota: Se puede personalizar cualquier rango de temperatura de -150℃ ~ +350℃ y cualquier capacidad de refrigeración. | |||||||||

Refrigeradores de alta temperatura

El enfriador puede utilizarse ampliamente en diversas industrias y laboratorios, y admite diseños personalizados.

| Temperatura | +5°C ~ +40°C | -25°C ~ +40°C | -45°C ~ +40°C | -80°C ~ +80°C | -100°C ~ +80°C | ||||

| Capacidad de refrigeración | 6 ~ 40kW | 2 ~ 15kW | 1 ~ 8kW | 0,6 ~ 3 kW | 1,5 ~ 3 kW | ||||

| Nota: Se puede personalizar cualquier rango de temperatura de -150℃ ~ +350℃ y cualquier capacidad de refrigeración. | |||||||||

Enfriadoras y calefactoras

Rango de control de temperatura: -120°C a +350°C

termostato de refrigeración y calefacción, ampliamente utilizado en diversas industrias.

| Temperatura | Serie -10 ~ +150°C | Serie -25 ~ +200°C | Serie -25 ~ +300°C | Serie -45 ~ +250°C | Serie -45 ~ +300°C | Serie -60 ~ +250°C | Serie -60 ~ +300°C | Serie -70 ~ +250°C | Serie -80 ~ +250°C | Serie -90 ~ +250°C | Serie -100 ~ +100°C | ||

| Capacidad de refrigeración | 1,5 ~ 15 kW | 1 ~ 200 kW | 1 ~ 200 kW | 0,45 ~ 200 kW | 0,9 ~ 25 kW | 0,25 ~ 60 kW | 0,75 ~ 25 kW | 0,4 ~ 15 kW | 0,3 ~ 80 kW | 0,2 ~ 80 kW | 0,45 ~ 80 kW | ||

| Nota: Se puede personalizar cualquier rango de temperatura de -150℃ ~ +350℃ y cualquier capacidad de refrigeración. | |||||||||||||

Enfriadoras de recirculación

Rango de control de temperatura: -45°C a +250°C

| Temperatura | Serie -25°C ~ +200°C | Serie -45°C ~ +250°C | |||||||

| Capacidad de refrigeración | 1 ~ 15 kW | 0,25 ~ 15 kW | |||||||

| Nota: Se puede personalizar cualquier rango de temperatura de -150℃ ~ +350℃ y cualquier capacidad de refrigeración. | |||||||||

LNEYA

LNEYA

简体中文

简体中文