Five Cooling Solutions for Cabinets

There are many solutions for cabinet cooling. Here are some common solutions:

1. Air conditioning cooling: Use the air conditioning system to provide cold air to the cabinet, send the cold air into the cabinet through the fan, and discharge the hot air out of the cabinet. This solution is suitable for large computer rooms or data centers and can provide stable temperature and humidity control.

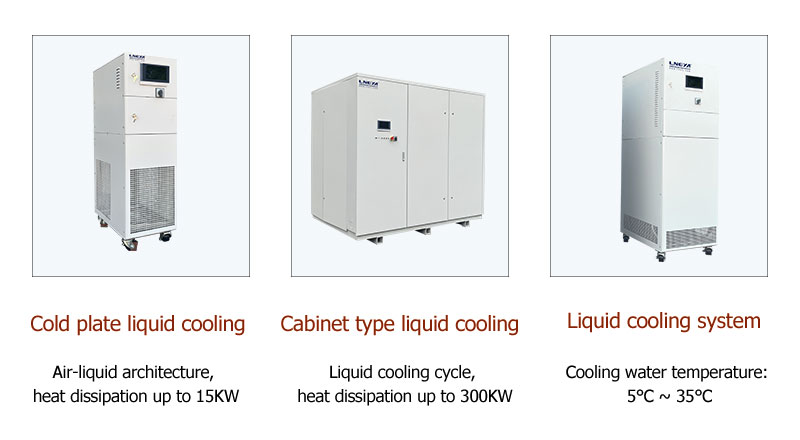

2. Water cooling: By installing water-cooling fins or water-cooling units inside the cabinet, the heat in the cabinet is dissipated through water. Water cooling solutions can provide higher heat dissipation efficiency, but require the installation of additional water cooling systems and piping.

3. Ventilation and cooling: Install a fan or air cooling system inside the cabinet to reduce the temperature inside the cabinet by increasing air flow. This solution is suitable for small computer rooms or a small number of servers. The cost is relatively low, but the cooling effect may be poor.

4. Cold aisle/hot aisle isolation: Isolate the cabinet according to the cold aisle and hot aisle, and reduce the temperature inside the cabinet by optimizing the path of hot and cold air circulation. This solution can improve heat dissipation efficiency, but requires reasonable planning and wiring of the computer room.

5. Use an environmental monitoring system: By installing temperature and humidity sensors and monitoring equipment, the temperature and humidity in the cabinet are monitored in real time, and the cooling plan is adjusted based on the monitoring results to keep the temperature in the cabinet within an appropriate range.

Based on actual needs and budget, you can choose a suitable cabinet cooling solution. When choosing a solution, factors such as energy consumption, cooling efficiency, cost, and maintainability need to be considered. At the same time, reasonable cabinet layout and space management are also key to improving cooling effect.

| Modelo | ZLFQ-15 | ZLFQ-25 | ZLFQ-50 | ZLFQ-75 | ZLFQ-100 | ZLFQ-150 |

| Rango de temperatura | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ |

| Agua de refrigeración | 5℃~30℃ Adopta válvula reguladora Siemens/Honeywell para controlar el flujo de agua de refrigeración. | |||||

| Precisión del control de temperatura | ±0.2℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ |

| control de flujo | 10~25L/min | 25~50L/min | 40~110L/min | 70~150L/min | 150~250L/min | 200~400L/min |

| El control de caudal se ajusta mediante un convertidor de frecuencia, la precisión es de ±0,3 L/min. | ||||||

| Capacidad de refrigeración (MAX) | 15 kW | 25 kW | 50 kW | 75 kW | 100 kW | 150 kW |

| Volumen de almacenamiento | 15L | 30L | 60L | 100L | 150L | 200L |

| Salmuera | Agua, aceite de silicona, líquido fluorado, solución acuosa de etilenglicol, etc. | |||||

| Canalización media | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 |

| Tamaño de la interfaz de entrada y salida | G3/4 | G1 | G1 | DN32 | DN40 | DN50 |

| Interfaz de agua de refrigeración | G3/4 | G1 | DN40 | DN50 | DN50 | DN65 |

| Caudal de agua de refrigeración 7~20℃ | 2,5 m³/h | 4 m³/h | 8m³/h | 13 m³/h | 17 m³/h | 25 m³/h |

| 380V 50HZ | 1kW | 1,5 kW | 3kW | 4kW | 5kW | 6kW |

| concha | Chapa laminada en frío pulverizada RAL7035 | |||||

| Modelo | ZLFQ-200 | ZLFQ-250 | ZLFQ-300 | ZLFQ-400 | ZLFQ-500 |

| Rango de temperatura | +5℃~35℃ | ||||

| Precisión de la temperatura | ±0.5℃ | ||||

| Control del caudal | 15~30m³/h | 20~35m³/h | 25~40m³/h | 30~60m³/h | 40~70m³/h |

| Capacidad de refrigeración(MAX) | 200 kW | 250 kW | 300 kW | 400 kW | 500 kW |

| Volumen de almacenamiento | 250L | 300L | 600L | 1000L | 1200L |

| Medio | Agua, aceite de silicona, líquido fluorado, solución acuosa de etilenglicol, etc. | ||||

| Canalización media | SUS304 | ||||

| Tamaño de la interfaz de entrada y salida | DN65 | DN65 | DN65 | DN80 | DN80 |

| Interfaz de agua de refrigeración | DN80 | DN80 | DN100 | DN100 | DN125 |

| Caudal de agua de refrigeración 7~20℃ | 34 m³/h | 43 m³/h | 51 m³/h | 69 m³/h | 86 m³/h |

| Alimentación 380V 50HZ | 7kW | 7kW | 8kW | 9kW | 13kW |

| concha | Chapa laminada en frío pulverizada RAL7035 | ||||

Ofrecemos diseño y fabricación de sistemas completos de control de temperatura. Desde modelos estándar hasta productos personalizados completos hasta 1000 toneladas. Nos especializamos en el servicio al cliente y nos dedicamos a ayudar a cada cliente a tener el sistema de control de temperatura óptimo para su necesidad específica.

Ofrecemos soluciones personalizadas no estándar.

Correo electrónico: lilia@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

LNEYA

LNEYA

简体中文

简体中文