CDU Liquid Cooling Data Center

Contactez-nous dès aujourd'hui pour une solution parfaite de contrôle de la température

Server computing power is growing rapidly, and the construction of large-scale data centers with high density and high energy consumption has become a necessary choice to balance computing power and environmental protection regulations. Currently, air conditioners used for server cooling have become a key factor in determining the PUE of data centers because their energy load is higher than that of IT equipment.

The refrigeration system is one of the important infrastructures of the data center. During the operation of high-density data centers, traditional air cooling faces problems of insufficient heat dissipation and serious energy consumption. Liquid cooling technology has become an optimal solution to reduce the PUE of the data center, which is above 15kW/cabinet. more economical advantages.

At present, liquid cooling technology has gradually been adopted in ultra-large data centers with high density and high power supply density around the world. Liquid cooling technology is to directly introduce the liquid cooling system into the server for heat dissipation, or even put the server and other equipment that need heat dissipation directly into the coolant (transmission media such as mineral oil or fluorinated liquid).

The heat is transferred through the liquid-cooled host and then dissipated into the air through the outdoor cooling tower. Since the specific heat capacity of liquid is much larger than that of air, the cooling efficiency is much higher than that of air cooling, and since the fan is omitted, the noise can also be reduced. The server thus achieves high density, low noise, low heat transfer temperature difference, and natural cooling throughout the year.

As the construction pace of ultra-high-density data centers accelerates, traditional air cooling can no longer meet the needs of high cost performance and low PUE. Therefore, liquid cooling technology has become the main path for building data centers in the future. Air cooling refers to a heat dissipation method that transfers the heat emitted by the server motherboard, CPU, etc. to the radiator module through the radiator, and then uses a fan or air conditioner to blow the heat away.

In recent years, heat dissipation solutions have evolved from traditional external computer room air conditioners to AHUs with natural cooling on the direct air side, and then to AHUs with natural cooling on the indirect air side. Technical innovations in air cooling systems continue to emerge, among which Baidu Yangquan is a typical example. Cloud computing center, etc. However, air cooling is still limited to using air as the refrigerant. The heat conduction process of air cooling is complex, the total thermal resistance is large, the heat transfer efficiency is low, and the temperature difference between high and low temperature heat sources is large during the heat exchange process. A lower outdoor low-temperature heat source is needed to guide the heat exchange process. conduct.

The CPU core temperature of liquid-cooled servers can be 20~30°C lower than the extreme temperature of air cooling, and the reliability will be greatly improved. Liquid-cooled servers do not require compressor cooling, which reduces the PUE value of the entire system to less than 1.2 throughout the year. At the same time, the server CPU can be overclocked and computing performance can be improved by 12%.

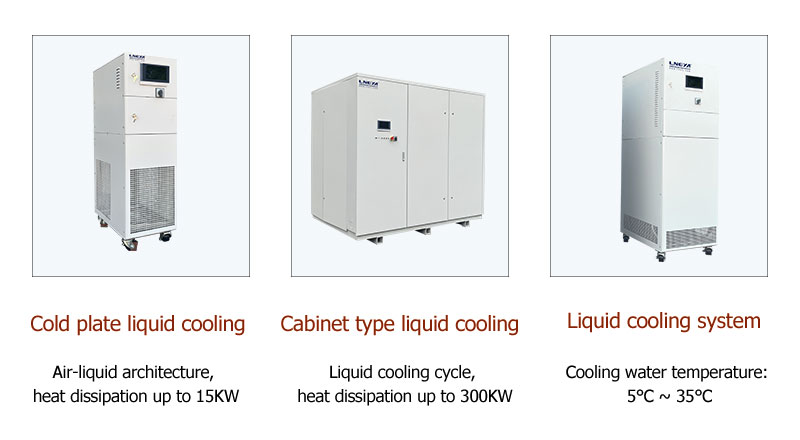

Cold plate liquid cooling has the highest maturity, and immersion liquid cooling and spray liquid cooling have better energy-saving effects.

Currently, three different liquid cooling solutions each have some application cases in the communications industry.

Among them, cold plate liquid cooling heating devices do not need to come into contact with coolant. They are the earliest in development and have high technological maturity. Cold plate liquid cooling uses micro-channel enhanced heat exchange technology and has extremely high heat dissipation performance. It is used in military radars and high-density data centers. , high-performance computers, power batteries and high-power LED heat dissipation fields. It is an effective application solution to solve the deployment of high-power consumption equipment, improve energy efficiency, reduce refrigeration operating costs, and reduce TCO.

Immersion and spray liquid cooling achieve 100% liquid cooling and have better energy-saving effects; immersion liquid cooling has obvious advantages in heat dissipation and energy saving, and has been widely used in the fields of supercomputing and high-performance computing.

| Modèle | ZLFQ-15 | ZLFQ-25 | ZLFQ-50 | ZLFQ-75 | ZLFQ-100 | ZLFQ-150 |

| Plage de température | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ | +5℃~35℃ |

| Eau de refroidissement | 5℃~30℃ Adopte une vanne de régulation Siemens/Honeywell pour contrôler le débit de l'eau de refroidissement. | |||||

| Précision du contrôle de la température | ±0.2℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ | ±0.5℃ |

| contrôle du débit | 10~25L/min | 25~50L/min | 40~110L/min | 70~150L/min | 150~250L/min | 200~400L/min |

| Le contrôle du débit est ajusté par un convertisseur de fréquence, la précision est de ±0,3L/min. | ||||||

| Capacité de refroidissement (MAX) | 15kW | 25kW | 50kW | 75kW | 100kW | 150kW |

| Volume de stockage | 15L | 30L | 60L | 100L | 150L | 200L |

| Brin | Eau, huile de silicone, liquide fluoré, solution aqueuse d'éthylène glycol, etc. | |||||

| Pipeline moyen | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 |

| Taille des interfaces d'entrée et de sortie | G3/4 | G1 | G1 | DN32 | DN40 | DN50 |

| Interface avec l'eau de refroidissement | G3/4 | G1 | DN40 | DN50 | DN50 | DN65 |

| Débit d'eau de refroidissement 7~20℃ | 2,5m³/h | 4m³/h | 8m³/h | 13m³/h | 17m³/h | 25m³/h |

| 380V 50HZ | 1kW | 1,5 kW | 3kW | 4kW | 5kW | 6kW |

| coquille | Tôle laminée à froid spray RAL7035 | |||||

| Modèle | ZLFQ-200 | ZLFQ-250 | ZLFQ-300 | ZLFQ-400 | ZLFQ-500 |

| Plage de température | +5℃~35℃ | ||||

| Précision de la température | ±0.5℃ | ||||

| Contrôle du débit | 15~30m³/h | 20~35m³/h | 25~40m³/h | 30~60m³/h | 40~70m³/h |

| Capacité de refroidissement(MAX) | 200kW | 250kW | 300kW | 400kW | 500kW |

| Volume de stockage | 250L | 300L | 600L | 1000L | 1200L |

| Moyen | Eau, huile de silicone, liquide fluoré, solution aqueuse d'éthylène glycol, etc. | ||||

| Pipeline moyen | SUS304 | ||||

| Taille des interfaces d'entrée et de sortie | DN65 | DN65 | DN65 | DN80 | DN80 |

| Interface avec l'eau de refroidissement | DN80 | DN80 | DN100 | DN100 | DN125 |

| Débit d'eau de refroidissement 7~20℃ | 34m³/h | 43m³/h | 51m³/h | 69m³/h | 86m³/h |

| Alimentation 380V 50HZ | 7kW | 7kW | 8kW | 9kW | 13kW |

| coquille | Tôle laminée à froid spray RAL7035 | ||||

Nous assurons la conception et la fabrication de systèmes complets de contrôle de la température. Des modèles standard aux produits personnalisés complets jusqu'à 1000 tonnes. Nous sommes spécialisés dans le service à la clientèle et nous nous efforçons d'aider chaque client à obtenir le système de contrôle de la température le mieux adapté à ses besoins spécifiques.

Nous fournissons des solutions personnalisées non standard.

Courriel : info@lneya.com ID WeChat : +8615251628237 WhatsApp : +86 17851209193

LNEYA

LNEYA

简体中文

简体中文