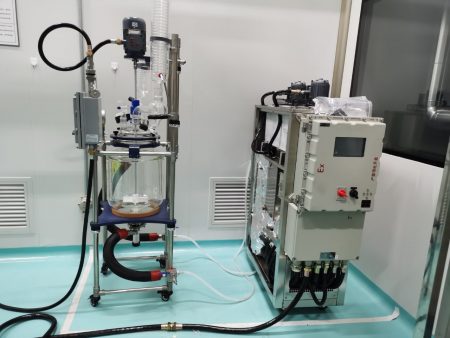

Heating and Cooling Reactor Chiller

In fields such as chemical industry, pharmaceuticals and materials science, reactors are key equipment for substance synthesis and processing. With the advancement of science and technology, traditional single-function reactors have gradually been unable to meet the needs of complex chemical reactions. The emergence of heating and cooling reactor chiller not only promotes the development of reactor technology, but also brings a series of challenges.

Technical promotion of heating and cooling reactor chiller

1. Improvement of temperature control accuracy: The heating and cooling reactor chiller can accurately control the temperature of the reaction system within a wide temperature range, which is crucial for fine chemical processes that require strict control of reaction conditions.

2. Enhancement of reaction efficiency: By integrating the heating and cooling system, the heating and cooling reactor chiller can achieve rapid temperature switching, thereby shortening the reaction time and improving production efficiency.

3. Optimization of energy utilization: Integrated design reduces energy loss, makes energy utilization more efficient, and helps reduce production costs and environmental impact.

4. Convenience of operation: Users can easily set and adjust reaction parameters through the advanced control system, which improves the convenience and safety of operation.

Challenges faced by heating and cooling reactor chiller

1. Increased technical complexity: The design and manufacturing of heating and cooling reactor chillers require a higher technical level, which places higher R&D and production capacity requirements on manufacturers.

2. Increase in cost investment: Compared with traditional reactors, the R&D and production costs of heating and cooling reactor chillers are higher, which may limit its promotion and application in small and medium-sized enterprises.

3. Increased difficulty in maintenance and repair: Due to the complexity of the system, maintenance and repair work has become more professional and difficult, requiring professional technical support.

4. Challenges of technological upgrading: With the continuous advancement of technology, heating and cooling reactor chillers need to be constantly updated to adapt to new process requirements, which poses continuous challenges to the company’s R&D capabilities.

As an innovative technology, heating and cooling reactor chiller has significantly promoted the development of reactor technology, but also brought many challenges. Enterprises need to evaluate their own technical strength and market demand, invest rationally in this area, and at the same time strengthen the construction of technical research and development and maintenance teams to cope with challenges and seize opportunities. For the industry, the development of heating and cooling reactor chiller indicates that reactor technology will become more intelligent, precise and efficient in the future, contributing to the sustainable development of the chemical industry.

We provide complete temperature control systems design and manufacturing. From standard models to complete customized products. We specialize in customer service and are dedicated to helping each customer have the optimal temperature control system for their specific need.

We provide non-standard customized solutions. Both single cooling chillers and cooling & heating combo units are available.

Email: lilia@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

Cooling and Heating Systems (SUNDI series)

- Temperature range: -120℃ ~ +350℃

- High-precision, intelligent temperature control

- Cooling capacity: 0.5kW ~ 1200kW

- Fully closed system to extend the service life of thermal fluid

- Each device is load tested for more than 12 hours

| Temperature range | -10 ~ +150°C series | -25 ~ +200°C series | -25 ~ +300°C series | -45 ~ +250°C series | -45 ~ +300°C series | -60 ~ +250°C series | -60 ~ +300°C series | -70 ~ +250°C series | -80 ~ +250°C series | -90 ~ +250°C series | -100 ~ +100°C series | ||

| Cooling Capacity | 1.5 ~ 15kW | 1 ~ 200kW | 1 ~ 200kW | 0.45 ~ 200kW | 0.9 ~ 25kW | 0.25 ~ 60kW | 0.75 ~ 25kW | 0.4 ~ 15kW | 0.3 ~ 80kW | 0.2 ~ 80kW | 0.45 ~ 80kW | ||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||||||

Cooling and Heating Systems (WTD series)

- (Micro channel / tube reactors specialized)

- Temperature range: -70℃ ~ +300℃

- High-performance circulation pump, more stable temperature control effect

- Wide temperature range to meet the needs of more industries

- Each device is load tested for more than 12 hours

| Temperature range | -70°C ~ +300°C | -45°C ~ +250°C | -70°C ~ +200°C | ||||||

| Cooling Capacity | 1.1 ~ 7.5kW | 1.5 ~ 5.5kW | 11 ~ 50kW | ||||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

Cooling and Heating Circulators

- Temperature range: -45℃ ~ +250℃

- Emerson Copeland compressor, reliable quality

- Self-diagnosis function, multiple safety protection devices

- Fully closed system to extend the service life of thermal fluid

- Each device is load tested for more than 12 hours

| Temperature range | -25°C ~ +200°C series | -45°C ~ +250°C series | |||||||

| Cooling Capacity | 1 ~ 15kW | 0.25 ~ 15kW | |||||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

Heating Circulators

- Temperature range: +50℃ ~ +300℃

- Large heat exchange area and fast heating speed

- Self-diagnosis function, multiple safety protection devices

- Closed circulation system, no oil mist at high temperatures

- Each device is load tested for more than 12 hours

| Temperature range | +50°C ~ +170°C (UC series) | +50°C ~ +300°C (UC series) | +50°C ~ +300°C (UST series) | ||||||

| Heating Capacity | 5.5 ~ 15kW | 3.5 ~ 130kW | 3.5 ~ 95kW | ||||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

TES Series (Temperature control for fuel and oil testing)

- Temperature range: -85℃ ~ +250℃

- Siemens PLC controller and other brand accessories

- Self-diagnosis function, multiple safety protection devices

- Fully closed circulation system, no oil mist at high temperatures

- Each device is load tested for more than 12 hours

| Temperature range | -45°C ~ +250°C series | -85°C ~ +200°C series | -60°C ~ +200°C series | ||||||

| Cooling Capacity | 0.3 ~ 25kW | 0.25 ~ 25kW | 3 ~ 60kW | ||||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

TCU Multi-reactors Temperature Control System

- Temperature range: -120℃ ~ +250℃

- Sealed, repeatable temperature control

- Built-in electric heating thermal oil auxiliary system

- Add cold and heat source heat exchange modules according to needs

- Each device is load tested for more than 12 hours

| Temperature range | -45°C ~ +250°C series | -120°C ~ +250°C series | Customized Temperature Control System | RT+10°C ~ +135°C | |||||

| Heating Capacity | 25 ~ 80kW | 25 ~ 80kW | Custom | 25 ~ 300kW | |||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

Recirculating Chillers / Refrigerated Circulator

The chiller can be widely used in various industries and laboratories, and supports customized design.

| Temperature range | -25°C ~ +30°C series | -45°C ~ +30°C series | -60°C ~ -20°C series | -80°C ~ -20°C series | -120°C ~ -70°C series | ||||

| Cooling Capacity | 0.8 ~ 30kW | 0.75 ~ 12kW | 0.4 ~ 6kW | 0.2 ~ 6kW | 0.3 ~ 5kW | ||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

Mini Chillers / Small Chillers

Mini Chillers / Small Chillers

The chiller can be widely used in various industries and laboratories, and supports customized design.

| Temperature range | -18°C ~ +30°C | +5°C ~ +35°C series | |||||||

| Cooling Capacity | 0.35 ~ 0.9kW | 1.8 ~ 50kW | |||||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

Low Temperature Chillers

We specialize in the production of low-temperature chillers with a temperature control range as low as -150°C, which can meet the refrigeration needs of different industries.

| Temperature range | -25°C ~ -5°C series | -45°C ~ -10°C series | -60°C ~ -10°C series | -80°C ~ -30°C series | -110°C ~ -50°C series | -150°C ~ -110°C series | |||

| Cooling Capacity | 12 ~ 360kW | 6 ~ 180kW | 6 ~ 180kW | 4 ~ 180kW | 2 ~ 120kW | 2.5 ~ 11kW | |||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

High Temperature Chillers

The chiller can be widely used in various industries and laboratories, and supports customized design.

| Temperature range | +5°C ~ +40°C | -25°C ~ +40°C | -45°C ~ +40°C | -80°C ~ +80°C | -100°C ~ +80°C | ||||

| Cooling Capacity | 6 ~ 40kW | 2 ~ 15kW | 1 ~ 8kW | 0.6 ~ 3kW | 1.5 ~ 3kW | ||||

| Note: Any temperature range from -150℃ ~ +350℃ and any cooling capacity can be customized | |||||||||

LNEYA

LNEYA

简体中文

简体中文