3 Cooling Methods for Energy Storage Battery Pack Thermal Management

完璧な温度制御ソリューションについては、今すぐお問い合わせください。

In the energy storage industry, the attention paid to thermal management is relatively high. The cooling methods of energy storage thermal management mainly include air cooling, liquid cooling, phase change cooling, and heat pipe cooling.

1. Air cooling technology

At present, air cooling technology is mainly used in container energy storage systems with low power density and communication base station energy storage systems. On the one hand, it is because the structure of the air-cooling system is simple, reliable, and easy to implement; on the other hand, because the energy storage system is not as strict as the power battery system on energy density and space, it can be obtained by increasing the number of batteries to achieve a lower working temperature. rate and heat production rate.

The air-cooled heat management system has an air-conditioning structure, including a floor-standing integrated type, a top-mounted integrated type, and a split type. The floor-standing integrated air conditioner is used in the energy storage container with reserved air-conditioning space. Usually, the air comes out from the top and is connected to the air duct inside the container to directly supply air to the battery pack accurately.

If there is no space to install an air conditioner inside the energy storage container, a top-mounted integrated air conditioner is required. The air conditioner is installed on the top of the container to cool the battery from the top.

The internal unit of the split air conditioner is installed in the battery pack, and the air is returned from the front to the back, and the air outlet of the air conditioner is connected to the air duct to directly cool the battery.

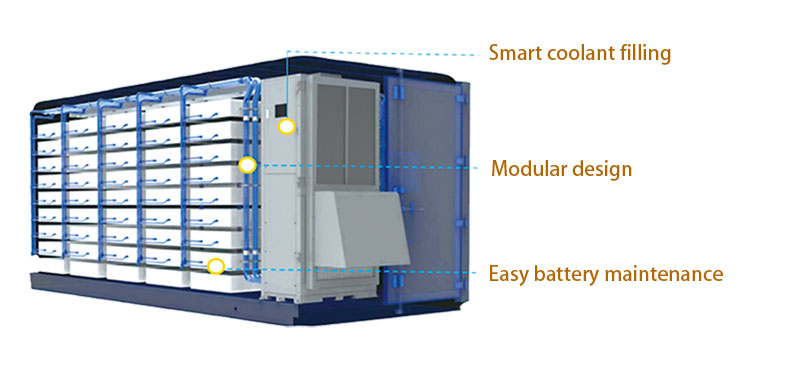

2. Liquid cooling technology

The liquid cooling scheme uses cooling liquids such as water, ethanol, and silicone oil to dissipate heat through indirect contact between the evenly distributed flow guide grooves on the liquid cooling plate and the battery cells. Its advantages include:

1) Close to the heat source for effective cooling;

2) Compared with the container air-cooling solution of the same capacity, the liquid cooling system does not need to design air ducts, and is more suitable for large-scale energy storage power stations;

3) Compared with the air-cooled system, due to the reduction of the use of mechanical components such as fans, the failure rate is lower;

4) Liquid cooling has low noise and saves system power consumption;

The core of the liquid cooling system of the energy storage battery pack thermal management cooling system is the chiller and the liquid cooling plate. Among them, the chiller includes compressors, condensers, throttles, evaporators, water pumps and other components. The liquid cooling plate is to process raw materials such as copper and aluminum into corresponding plates. The production process of the liquid cooling plate is divided into needle welding, blowing, etc. Expansion, die casting, stamping, friction stir welding, etc.

With the start of new energy power stations, off-grid energy storage and other energy storage power stations with larger battery capacity and higher system power density, the energy storage system has greater energy density and calorific value, and has higher requirements on life and service life, which will promote the industry to become more Multi-turn adopts liquid cooling solution.

3. Phase change cooling

Phase change cooling is a cooling method that utilizes the phase change of phase change materials to absorb heat. The selection of phase change materials has a greater impact on the heat dissipation effect of the battery. When the selected phase change material has a larger specific heat capacity and a higher heat transfer coefficient The higher the value, the better the cooling effect under the same conditions, otherwise the worse the cooling effect.

Phase change cooling has the advantages of compact structure, low contact thermal resistance, and good cooling effect, but the phase change material itself does not have the ability to dissipate heat, and the absorbed heat needs to be exported by the liquid cooling system and air cooling system, otherwise the phase change material cannot continue to absorb heat . In addition, phase change materials take up space and are expensive.

製品とソリューション

| モデル | CNYL -45 |

| 冷却能力 | 45KW |

| 温度制御精度 | ±0.5℃ リアルタイム温度記録 |

| 二次冷媒 | エチレングリコール不凍液、冷媒循環システムの完全密閉設計 |

| 冷媒 | R410A |

| フロー | 300L/min~400L/min 設定表示履歴 |

| 低圧電気 | シュナイダー/シーメンス |

| 表示画面 | 7インチカラータッチスクリーン |

| パワー | 380V 50HZ は 220V60HZ 460V 60HZ を選びます |

| シェル素材 | 冷間圧延シートスプレー REL7035 |

| 内部配管 | SUS304 |

| モデル | CNYL-5 | CNYL-8.5 |

| 冷却能力 | 5KW | 8.5KW |

| 精度 | ±0.5℃ リアルタイム温度記録 | ±0.5℃ リアルタイム温度記録 |

| 最低水入口温度 | 15℃(バッテリーシステムによりカスタマイズ可能) | 13℃(バッテリーシステムによりカスタマイズ可能) |

| システム圧力センサー検出 | 液体出口圧力、液体入口圧力、冷凍システム高低圧力 | |

| COP | *2.0 | *2.2 |

| コンプレッサー | ハーメチックコンプレッサー(1セット) | 34cm3/rev完全密閉式スクロールコンプレッサー(1セット) |

| 冷媒 | R410A | R410A |

| ディスプレイ | 7インチカラータッチスクリーン | 7インチカラータッチスクリーン |

| 動作周囲温度範囲 | -45℃~55℃ | |

| 制御電圧範囲 | 18-32V | 18-32V |

| 冷凍高圧最大出力 | 2.2KW | 3.5KW |

| 冷凍機の平均投入電力(kW) | +1.5kwadjustable頻度 | +2kwadjustable周波数 |

| COP | *2.0 | *2.2 |

| モデル | CHDYL-4 |

| 冷却能力 | 4KW |

| 精度 | ±リアルタイム温度記録 |

| コンプレッサー | ハーメチックコンプレッサー(1セット) |

| 冷媒 | R134A |

| ディスプレイ | 7インチカラータッチスクリーン |

| 制御システム | PLC |

| コミュニケーション | CAN |

| 動作周囲温度範囲 | -45℃~55℃ |

温度制御システムの設計から製造まで。標準モデルから完全なカスタマイズ製品まで 1000トン.私たちはカスタマーサービスに特化し、お客様一人ひとりのニーズに合った最適な温度制御システムを提供することに専念しています。

非標準のカスタマイズされたソリューションを提供します。

Eメール info@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

LNEYA

LNEYA

简体中文

简体中文