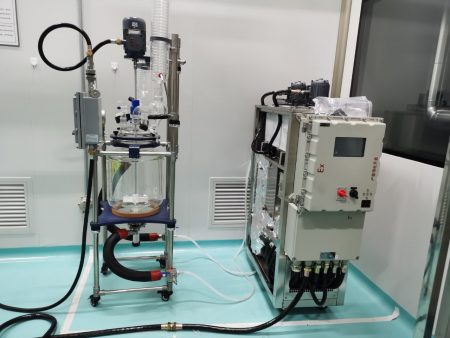

Single Fluid Heating and Cooling Systems for Reactors

완벽한 온도 제어 솔루션을 위해 지금 바로 문의하세요.

Principle of single fluid heating and cooling systems for reactors

1. Temperature sensor: Reactor temperature control systems usually use temperature sensors to monitor the temperature of the reactor in real time.

Common temperature sensors include thermocouples and thermistors, which convert temperature changes into electrical signals.

2. Controller: The controller is a component of the reactor temperature control system. It receives the signal from the temperature sensor and controls it according to the set temperature range.

The controller usually includes a PID control algorithm that can automatically adjust the output power of the heating or cooling device based on the difference between the real-time temperature and the set temperature to achieve stable temperature control.

3. Heating and cooling device: The heating and cooling device is the execution component of the reactor temperature control system. It adjusts the temperature of the reactor according to the instructions of the controller.

Common heating devices include electric heating wires and electric heating rods, while cooling devices can be cold water circulation systems or refrigerators.

Application of single fluid heating and cooling systems for reactors

1. Chemical synthesis: In the process of chemical synthesis, temperature is an important parameter.

The reactor temperature control system can help experimentalists control the stability of temperature during synthesis reactions and improve yield and product purity.

At the same time, the temperature control system can also avoid side reactions or product degradation caused by temperature fluctuations and improve the repeatability of the synthesis process.

2. Biological reactions: In biological reactions, the activity of cells or enzymes is usually closely related to temperature.

The reactor temperature control system can provide a stable temperature environment, maintain the activity of cells or enzymes, and improve reaction efficiency.

In addition, the temperature control system can also help control the rate and product selectivity of biological reactions, which is of great significance to the fields of bioengineering and pharmaceuticals.

3. Materials: In materials, temperature control has an important impact on the structure and performance of the material.

Single fluid heating and cooling systems for reactors can provide precise temperature control, help personnel observe material property changes at different temperatures, and provide important data for the development and application of new materials.

완벽한 온도 제어 시스템 설계 및 제조를 제공합니다. 표준 모델부터 완벽한 맞춤형 제품까지 900 . 당사는 고객 서비스를 전문으로 하며 각 고객이 특정 요구에 맞는 최적의 온도 제어 시스템을 갖출 수 있도록 최선을 다하고 있습니다.

비표준 맞춤형 솔루션을 제공합니다. 단일 냉각 냉각기와 냉각 및 난방 콤보 장치를 모두 사용할 수 있습니다.

이메일: info@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

냉각 및 난방 냉각기

(맞춤형 디자인)

온도 제어 범위: -120°C ~ +350°C

다양한 산업 분야에서 널리 사용되는 냉난방 온도 조절기입니다.

| 온도 범위 | -10 ~ +150°C 시리즈 | -25 ~ +200°C 시리즈 | -25 ~ +300°C 시리즈 | -45 ~ +250°C 시리즈 | -45 ~ +300°C 시리즈 | -60 ~ +250°C 시리즈 | -60 ~ +300°C 시리즈 | -70 ~ +250°C 시리즈 | -80 ~ +250°C 시리즈 | -90 ~ +250°C 시리즈 | -100 ~ +100°C 시리즈 | ||

| 냉각 용량 | 1.5 ~ 15kW | 1~200kW | 1~200kW | 0.45 ~ 200kW | 0.9 ~ 25kW | 0.25 ~ 60kW | 0.75 ~ 25kW | 0.4 ~ 15kW | 0.3 ~ 80kW | 0.2 ~ 80kW | 0.45 ~ 80kW | ||

| 참고: -150℃ ~ +350℃의 모든 온도 범위와 모든 냉각 용량을 맞춤 설정할 수 있습니다. | |||||||||||||

재순환 히터 냉각기

(맞춤형 디자인)

온도 제어 범위: -45°C ~ +250°C

| 온도 범위 | -25°C ~ +200°C 시리즈 | -45°C ~ +250°C 시리즈 | |||||||

| 냉각 용량 | 1 ~ 15kW | 0.25 ~ 15kW | |||||||

| 참고: -150℃ ~ +350℃의 모든 온도 범위와 모든 냉각 용량을 맞춤 설정할 수 있습니다. | |||||||||

LNEYA

LNEYA

简体中文

简体中文