Liquid Cooling Battery Pack

Contact us today for the perfect temperature control solution

The liquid cold plate of new energy battery pack is a key component of electric vehicles. It can effectively dissipate heat and ensure the stability and safety of the battery. The salt spray test can simulate the corrosion situation in the marine environment and verify the durability and reliability of the battery pack’s liquid-cooled plate in harsh environments. Ensure that electric vehicles can maintain stable operation in different environments and improve their service life and safety.

The liquid cold plate of the new energy vehicle battery pack is a key component used to control the battery temperature. Its main function is to absorb the heat generated by the battery through the circulating liquid and dissipate the heat to the surrounding environment to maintain the normal operation of the battery. temperature. The design and performance of the liquid cooling plate have an important impact on the performance and life of the battery pack, so it has been widely used in the field of new energy vehicles.

At present, the main types of liquid cooling plates in new energy vehicle battery packs include: DC liquid cooling plates, indirect liquid cooling plates and direct liquid cooling plates.

1. DC liquid cooling plate

DC liquid cooling plate is one of the earliest liquid cooling plates used in new energy vehicle battery packs. Its working principle is to directly enter the liquid cooling plate from the inlet, pass through the battery pack, and then discharge it from the outlet. During the flow of liquid, the liquid can effectively take away the heat generated by the battery pack, thereby achieving the purpose of controlling the battery temperature. The DC liquid cooling plate has the advantages of simple structure, low manufacturing cost, and good heat dissipation effect. However, its disadvantage is that the flow rate and temperature of the liquid are difficult to control, and uneven cooling and heating are prone to occur.

2. Indirect liquid cooling plate

The indirect liquid cooling plate is an improved liquid cooling plate based on the DC liquid cooling plate. It works by transferring the heat generated by the battery pack to the liquid through a heat exchanger, which then removes the liquid. This can achieve precise control of the flow rate and temperature of the liquid and avoid uneven hot and cold conditions. However, its disadvantage is that the structure is relatively complex and the manufacturing cost is high.

3. Direct liquid cooling plate

Direct liquid cooling plate is a new type of liquid cooling plate. Its working principle is to flow liquid directly through the battery pack through micro channels to achieve heat transfer and dissipation. The direct liquid cooling plate has the advantages of high heat dissipation efficiency, simple structure, and light weight. It can effectively control the battery temperature and improve the life and performance of the battery pack. However, its disadvantages are that it is difficult to manufacture and the cost is high.

The selection of liquid cooling plates for new energy vehicle battery packs needs to be based on specific application scenarios and needs. Different types of liquid cooling plates have their own advantages and disadvantages. All factors need to be considered comprehensively to select the most suitable liquid cooling plate to ensure the normal operation and life of the battery pack.

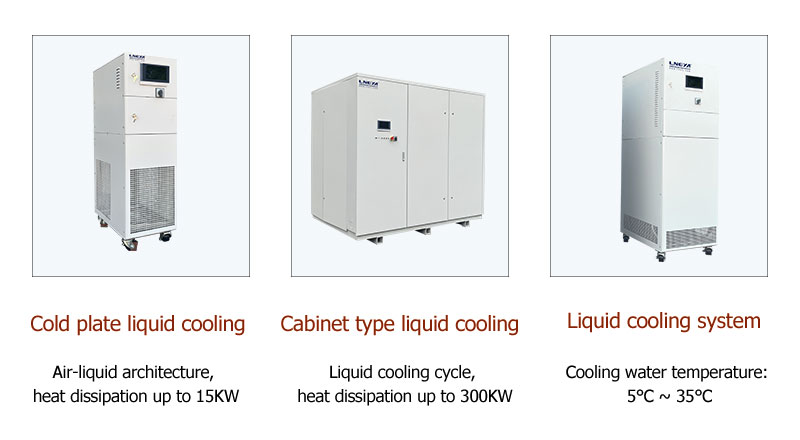

We provide complete temperature control systems design and manufacturing. From standard models to complete customized products up to 900 tons. We specialize in customer service and are dedicated to helping each customer have the optimal temperature control system for their specific need.

We provide non-standard customized solutions. Both single cooling chillers and cooling & heating combo units are available.

Email: info@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

LNEYA

LNEYA

简体中文

简体中文