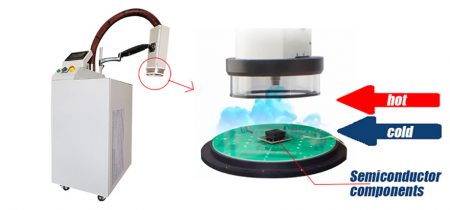

Thermal Air Conditioning Unit

The thermal air conditioning unit is now very active in the field of thermal and cooling testing of electronic components/modules. Because it is stable during constant temperature testing, it can be stably maintained at a certain temperature point. The accuracy can reach ±1°C; the temperature changes quickly during temperature shock: -55°C~+125°C <10 seconds; Really achieve the purpose of temperature “shock”; the temperature change time is controllable and the operation can be programmed.

1. The output airflow cover of the testing machine will cover the tested product to form a relatively closed space testing chamber. The high-temperature or low-temperature airflow output by the testing machine will cause the surface temperature of the tested product to change drastically, thereby completing the corresponding high and low temperature impact test. ;

2. A single IC or other component among many components can be isolated and subjected to high and low temperature shocks independently without affecting other surrounding components. Compared with the traditional hot and cold shock test chamber, the temperature change impact rate is faster.

Applications of thermal air conditioning unit:

Chips, microelectronic devices, integrated circuits (SOC, FPGA, PLD, MCU, ADC/DAC, DSP, etc.).

Flash memory, UFS, eMMC.

PCBs, MCMs, MEMS, IGBT, sensors, small module components optical communication (such as transceiver high and low temperature testing, SFP optical module high and low temperature testing, etc.).

Other electronic industries, aerospace new materials, laboratory research.

AES Series Jet Impact Testing Machine

Temp Control Range: -120°C ~ +225°C

LNEYA

LNEYA

简体中文

简体中文