Thermal Test System

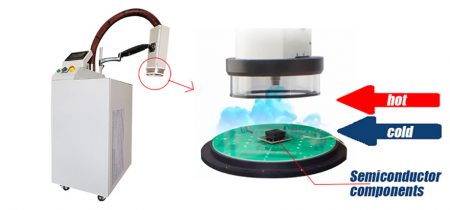

The thermal test system is an indispensable test equipment in the fields of optical communications, chips, integrated circuits, laboratory research and other fields. During the reliability test process, many test requirements need to be completed with the thermal test system, which is used to test and determine chips, The parameters and performance of microelectronic devices and other products and materials after temperature environment shock changes in high and low temperature tests. Use a stand-alone air-cooled refrigeration system. A low-temperature refrigeration cycle, its connected container is an evaporative condenser. The evaporative condenser also plays the role of energy transfer. It transfers the heat energy in the working room through the single-stage refrigeration system to achieve constant temperature. The design of the refrigeration system applies energy adjustment technology, an effective processing method that can not only ensure the normal operation of the refrigeration unit, but also effectively adjust the energy consumption and cooling capacity of the refrigeration system, reducing the operating costs of the refrigeration system. and the failure rate drops to a more economical state.

Functional features of thermal test system:

1. The thermal test system converts temperature in an instant with a fast conversion rate. It takes about 10 seconds to convert between -55℃ and +125℃. Therefore, it is usually called an ultra-high-speed high and low temperature airflow impact machine, and the temperature impact is in a non-linear situation. Completed next. The principle of temperature shock requires that during high-temperature testing, the high temperature is automatically transported to the heating head through the control system to achieve the effect of high-temperature shock. The same is true for low-temperature shock to achieve the purpose of temperature shock.

2. The temperature change is to complete cooling and heating within the specified time. For example, for a device with a temperature range of -55 degrees to 120 degrees Celsius, if the slope is set to 10 degrees Celsius/min, it will take 17 minutes to drop from 120 degrees Celsius to -55 degrees Celsius. However, generally speaking, high and low temperature cycle test systems do not need to set the slope separately. It can be completed from 120℃ to -55℃ in about 10 seconds, which is unmatched by ordinary high and low temperature testing machines.

We provide complete temperature control systems design and manufacturing. From standard models to complete customized products. We specialize in customer service and are dedicated to helping each customer have the optimal temperature control system for their specific need.

We provide non-standard customized solutions. Both single cooling chillers and cooling & heating combo units are available.

Email: lilia@lneya.com WeChat ID: +8615251628237 WhatsApp: +86 17851209193

AES Series Jet Impact Testing Machine

Temp Control Range: -120°C ~ +225°C

LNEYA

LNEYA

简体中文

简体中文